Alphabetical Index

Browse by Elements

Keyword Search

ASTM Electrolytes

Macro Etchants

Micro Etchants

Named Etchants

New Etchants

Al and Al Alloys

Cu and Cu Alloys

Fe and Fe Alloys

Ni and Ni Alloys

Carbide Etchants

Fluoride Etchants

Nitride Etchants

Other Etchants

Oxide Etchants

Phosphide Etchants

Single Crystal Etchants

Thin Film Etchants

Wafer Etchants

Help

Home

Lapping Tracks

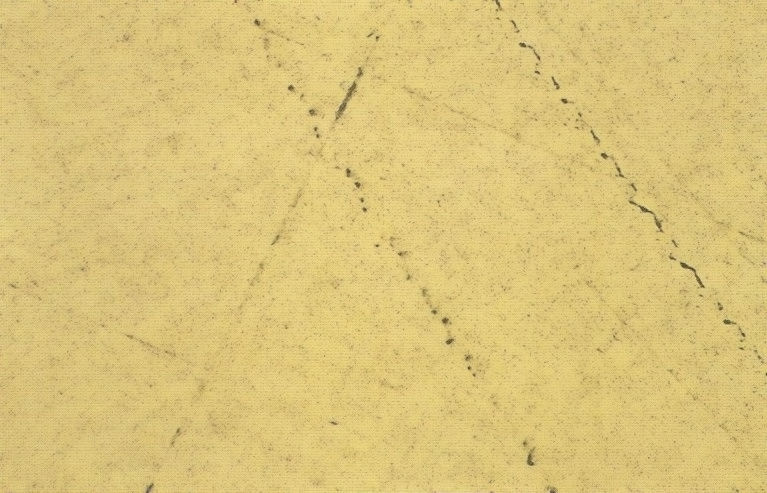

Example: Lapping tracks on Zicalloy, Mag. 200x.

These are indentations on the sample surface made by abrasive particles

moving freely on a hard surface. There are no scratches, like from a

cutting action. Instead, there are the distinct tracks of particles

tumbling over the surface without removing material. If abrasive particle

is not held in a fixed position while the sample is passing over it, it will

start rolling. Instead of removing, cuttingm chips of matrial, the grain

is forced into the sample material, creating deep deformation, and only

pounding small particles out of the sample surface.

Reference: Metalog Guide, page 92-93,

Struers A/S, 2610 Rodovre, Dennmark. Note: Image and text by courtesy of Struers A/S company.