Alphabetical Index

Browse by Elements

Keyword Search

ASTM Electrolytes

Macro Etchants

Micro Etchants

Named Etchants

New Etchants

Al and Al Alloys

Cu and Cu Alloys

Fe and Fe Alloys

Ni and Ni Alloys

Carbide Etchants

Fluoride Etchants

Nitride Etchants

Other Etchants

Oxide Etchants

Phosphide Etchants

Single Crystal Etchants

Thin Film Etchants

Wafer Etchants

Help

Home

Relief

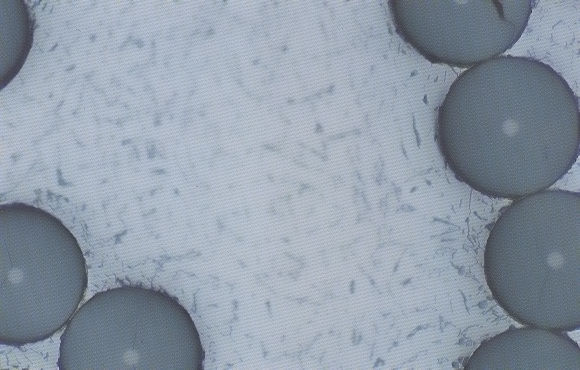

Example: B4C fibres in AlSi, relief between fibres and base material, Mag. 200x.

Material from different phases is removed at different rates, due to

varying hardness or wear rate of the individual phases. Relif does

normally first occur during polishing. The most important parameters

to avoid relief are preparation time and polishing cloth. The preparation

time should be kept as short as possible. When developing a new method

the samples have to be checked in short intervals, 1-2 min. The polishing

cloths have a strong influence on the planeness of the sample. Polishing

cloth with low resilience produces samples with les relief than cloth

with high resilience.

Reference: Metalog Guide, page 74-75,

Struers A/S, 2610 Rodovre, Dennmark. Note: Image and text by courtesy of Struers A/S company.