Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Cr23C6 and Cr7C3 carbides in heat resistant steel

Table 1: Chemical composition of the steel samples (wt.%).

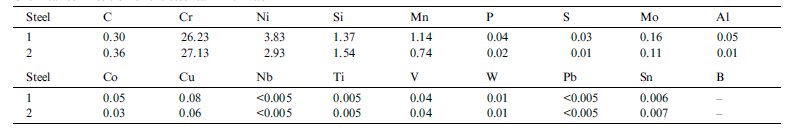

Figure 1: As-cast microstructure of steel 1. Scale bars: 100 µm.

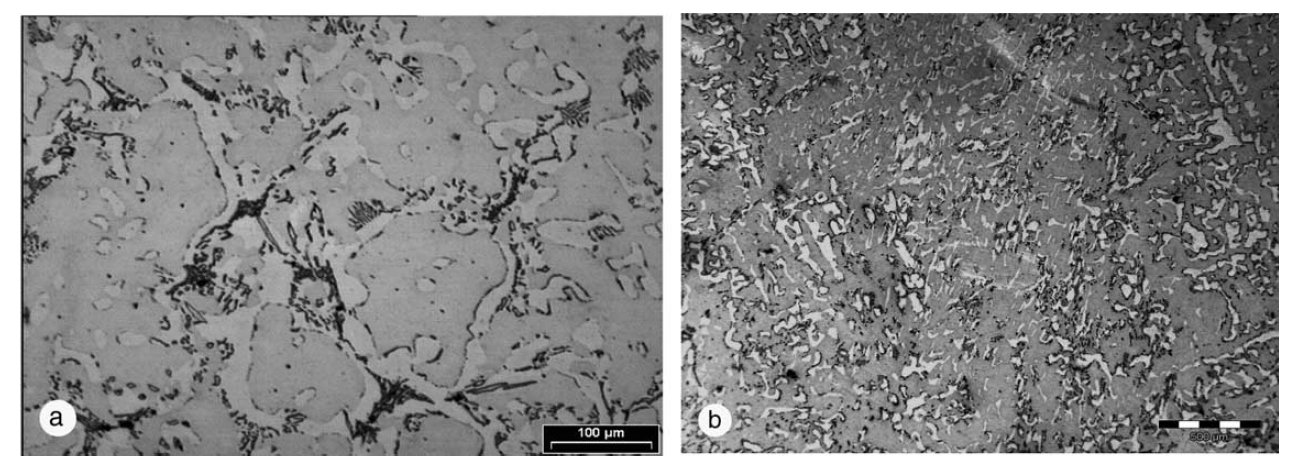

Figure 2: As-cast microstructure of steel 2. Scale bars: 100 µm.

Table 2: Carbides observed in the steel samples.

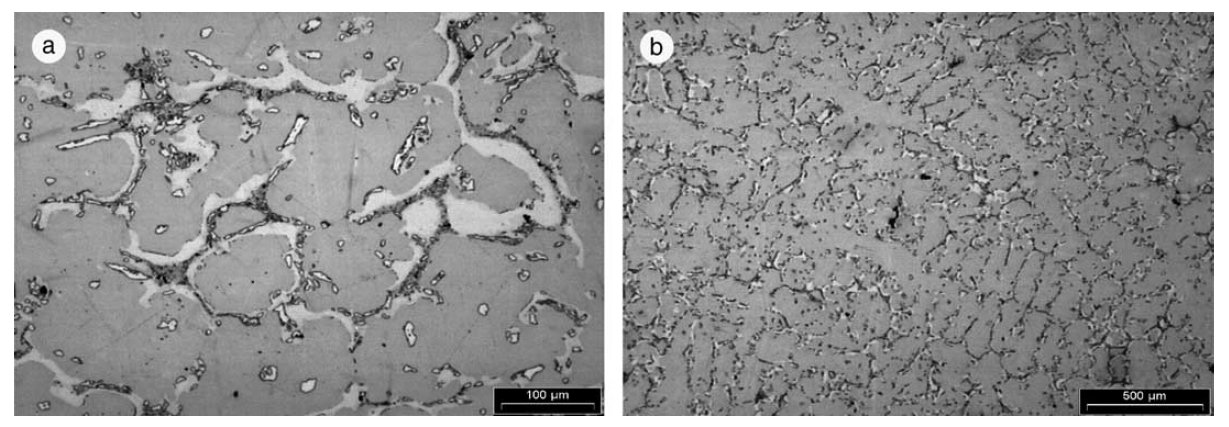

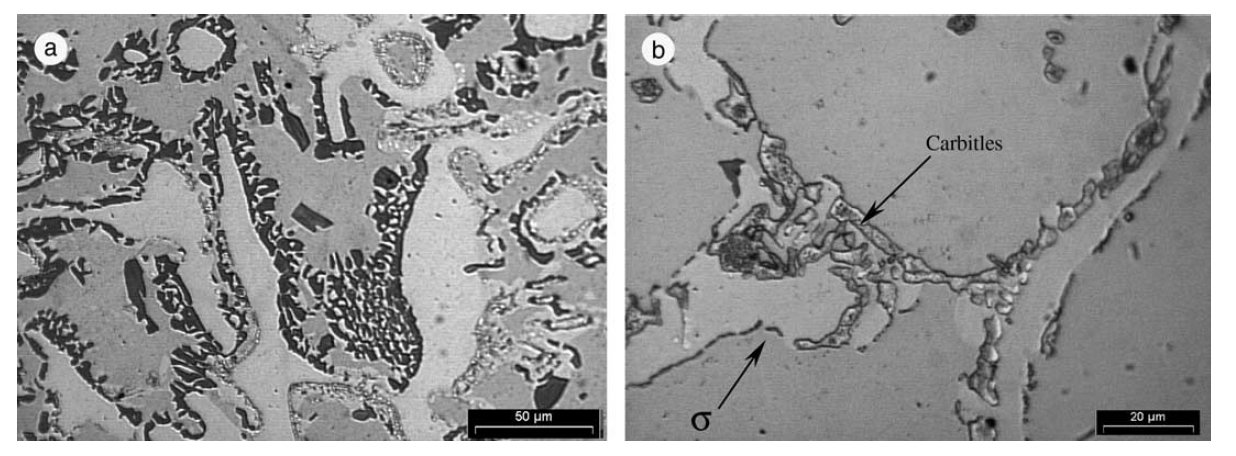

Figure 3: Microstructures of steels 1 and 2 after heat treatment at 1023 K for 50 h, of the as-cast samples; (a) steel 1, (b) steel 2. Scale bars: 50, 20 µm.

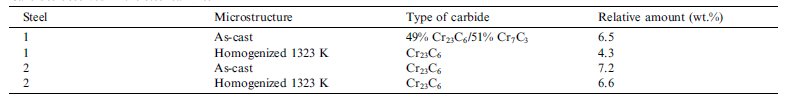

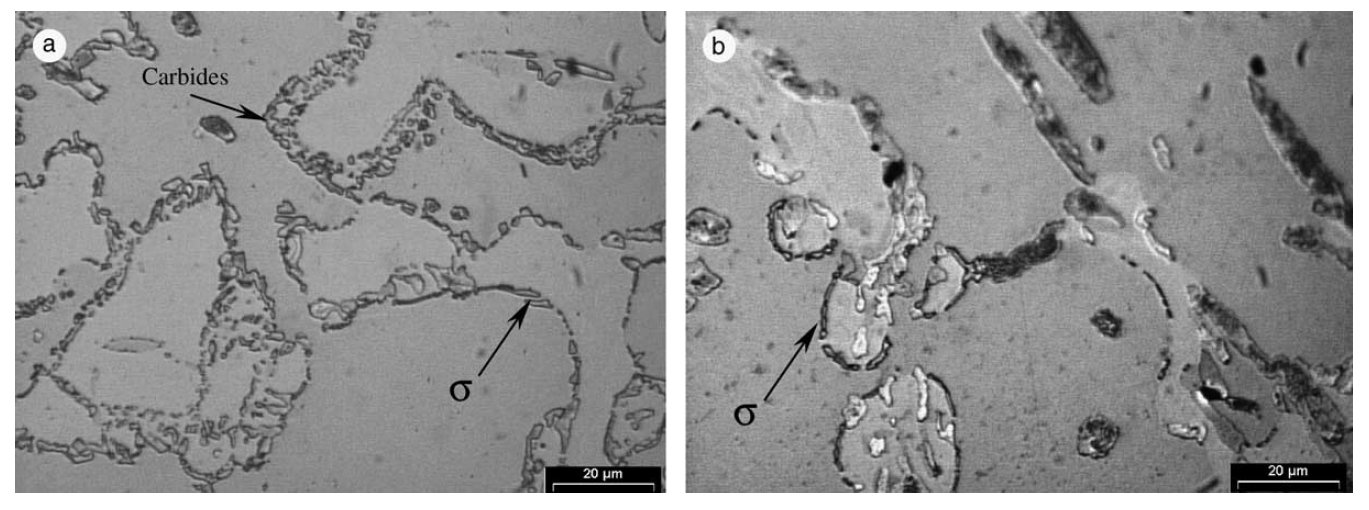

Figure 4: Microstructures of steels 1 and 2 after heat treatment at 1023 K for 50 h, of the samples homogenized at 1323 K. (a) Steel 1, (b) steel 2. Scale bars: 20 µm.

Carbide name: Cr23C6, Cr7C3

Record No.: 1031

Carbide formula: Cr23C6, Cr7C3

Carbide type: M23C6, M7C3

Carbide composition in weight %: No data

Image type: LM, SEM

Steel name: Heat resistant steel

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: No data

Other designation: No data

Steel group: Heat-resistant steels

Steel composition in weight %: See the table 1.

Heat treatment/condition: The chemical composition of the castings analyzed in

this study, as determined by means of emission spectrometry

(SPECTROLAB), is given in Table 1, where

the samples were labeled as steels 1 and 2. The figures

match the usual composition range stated for HC-type

steel (UNS J92605, A297, A608); slight differences in

composition can be observed for corresponding elements

in both samples. The Sigma-phase precipitation

treatment for steels 1 and 2 (1023 K for 50 h) was performed

on the as-cast microstructure and also after

homogenization annealing at 1323 K for 6 h. The

microstructural characterization of both alloys was

carried out by means of quantitative metallography

(ZEISS AXIOTECH, OLYMPUS BX60 and OLYMPUS

VANOX) and scanning electron microscopy

(JEOL JSM 840). The specimens were etched with

Emanuel reagent (30 g K3FeCN6, 30 g KOH, 60 ml

H2O) at 323 K for 25 s. The component phases were

quantitatively determined by image analysis. On the

other side, the carbides were identified by means of Xray

diffraction (SIEMENS D5000, monochromatized

Cu Ka radiation, k ¼ 0:15406 nm, 40 kV, 30 mA) after

extraction by electrochemical dissolution at 1,5 V (5 g

C2H2O4, 200 ml HCl, 1000 H2O).

Note: The influence of solidification microstructure on r-phase precipitation in two refractory stainless steels (26Cr–3Ni) with different

microstructures is analyzed. Depending upon cooling rates the existence of Cr7C3 strongly increases the r-phase precipitation rate,

whereas Sigma precipitation is delayed when this carbide is not present in the alloy.

The microstructure of the as-cast samples is shown in

Figs. 1 and 2, where the bright etching constituent is

austenite while ferrite is depicted by the dark etching

areas. In Fig. 1(a) two types of primary carbides can be

observed, one of them being distributed as small islands

inside the austenite grains and the other one precipitated

as an eutectoid component along the austenite–ferrite

interface. On the other side, only one type of carbide

was found in steel 2, as disclosed in Fig. 2(a). The X-ray

identification of the carbides is detailed in Table 2; here

Cr23C6 and Cr7C3 were detected in steel 1 in the weight

ratio of 49/51 while only Cr23C6 was contained in steel 2.

The total amount of extracted carbide was approximately

7 wt.%. Figs. 1(b) and 2(b) show the size of the

solidification dendrites, which are very much smaller in

steel 2 as compared with steel 1, which suggests that steel

2 solidified at a faster rate. The microstructure of the ascast

samples after 50 h of annealing at 1023 K are shown

in Fig. 3, where it can be observed that r-phase nucleates

along the austenite–ferrite interface and grows into

the ferrite grains. The relative amount of r-phase was

about 20 wt.% in steel 1 but only a few % in steel 2. On

the other hand, Cr23C6 was the only type of carbide

contained in both steels after homogenization of the ascast

samples at 1323 K for 6 h. In fact, according to

Table 2 the Cr7C3 had completely disappeared. Samples treated at 1023 K for 50 h after homogenization at 1323

K are shown in Fig. 4, where Sigma-phase is not yet visible.

Links: No data

Reference: Not shown in this demo version.