Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Carbides in 0.57C-1.96Si-0.16Mn-1.02Cr steel

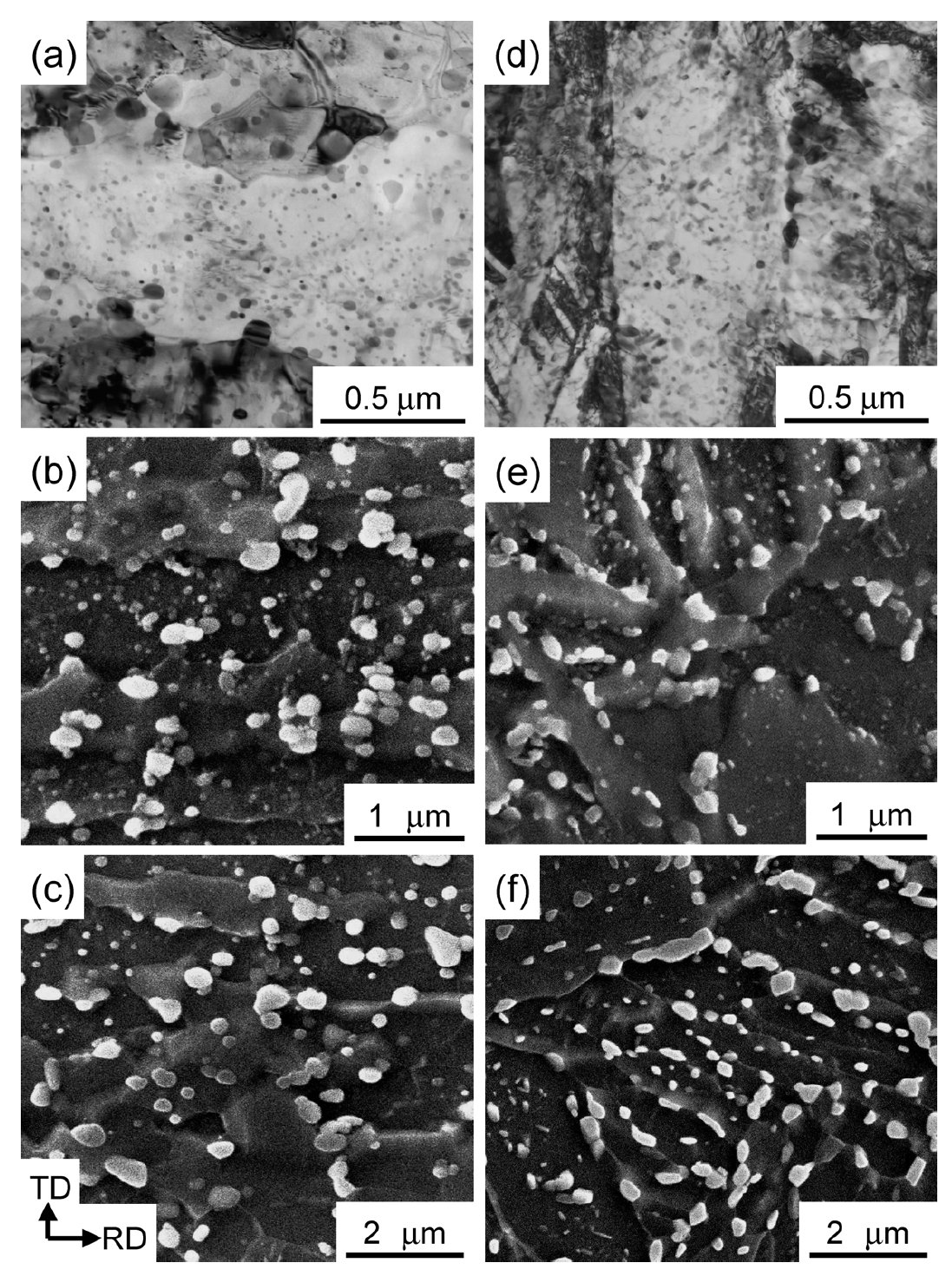

Figure 1: Carbide microstructures of the samples that were tempformed

at 500 (a), 600 (b) and 700°C (c) and were conventionally

quenched and tempered at 500 (d), 600 (e)

and 700°C (f). Scale bars: 0.5, 1, 2 µm.

Carbide name: No data

Record No.: 1077

Carbide formula: No data

Carbide type: No data

Carbide composition in weight %: No data

Image type: SEM, TEM

Steel name: 0.57C-1.96Si-0.16Mn-1.02Cr

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: No data

Other designation: No data

Steel group: Structural steels

Steel composition in weight %: 0.57% C, 1.96% Si, 0.16% Mn, 0.001% P, 0.001% S, 0.041% Al, 1.02% Cr, 0.002% Mo, 0.0018% N, 0.0005% O.

Heat treatment/condition: A 100 kg ingot was prepared by vacuum melting and casting, homoghomogenized

at 1200°C, and then hot-rolled to a plate with a

thickness of 4 cm. A 12 by 4 by 4 cm block was cut out of

the plate, heated to 1200°C, hot-rolled to a square bar with

a cross section area of 10 cm2, solution-treated at 1200°C

for 60 min, and water quenched to obtain a martensitic

structure without any coarse undissolved carbides. The average

prior-austenite grain size of the quenched bars was

210m m and the hardness was HV 850. The quenched bars

were tempered at 500, 600 and 700°C for 90 min, subjected

to multi-pass caliber-rolling at the respective temperatures

to square bars with a cross section area of 2 cm2, and air

cooled (tempformed (TF) samples). The accumulative reduction

in area through tempforming was 80% in ten

passes, which corresponds to an equivalent strain of 1.8.

Note that the samples were held for 5 min in a furnace after

every three passes during the rolling and passed through

twice for the final groove to control the cross sectional

shape of the bars, namely the pass schedule was 3-3-4 at

each temperature. To obtain conventional quenched and

tempered samples with the same tensile strengths for comparison,

normalized bars were austenitized at 880°C for 30

min, followed by oil quenching, tempered at 500, 600 and

700°C for 90 min, and then water cooled (QT samples).

The QT samples had an average prior-austenite grain size

of 26 µm and showed random textures.

Note: The deformation of tempered martensitic structures, namely tempforming treatments, were applied to a

0.6C–2Si–1Cr steel at 500, 600 and 700°C using multi-pass caliber-rolling with an accumulated area reduction

of 80%. The tensile and Charpy impact properties were investigated to make clear the relation between

the microstructure and the delamination behavior of the tempformed (TF) samples. The tempforming treatments

resulted in the evolution of ultrafine grain structures with strong <110>//rolling direction (RD) fiber deformation

textures and fine spheroidized cementite particles distributions. In contrast to the ductile-to-brittle

transition of the conventional quenched and tempered (QT) samples, the TF samples exhibited inverse temperature

dependences of the impact toughness due to the delaminations, where the cracks branched in the

longitudinal direction (//RD) of the impact test bars. As a result, high strength with excellent toughness was

achieved in the TF samples. A yield strength of 1364 MPa and a V-notch Charpy absorbed energy of 125 J

were obtained at room temperature in the sample that was tempformed at 500°C. The delamination was

shown to occur due to the microstructural anisotropy of the TF samples, and the dominating factors controlling

the delamination toughening were the transverse grain size, the grain shape and the .110.//RD fiber deformation

texture. The discussion also indicated that the ultra refinement of the transverse grain structure

was the key to enhancing both the yield strength and the toughness of the TF steel while lowering the ductile-

to-brittle transition temperature.

Figure 1 are TEM and SEM images showing morphologies

and distributions of carbide particles of the TF and QT

samples. Spheroidized cementite particles are dispersed in

all of the TF samples. Relatively large cementite particles

exist on the (sub) boundaries of the matrix ferrite grains,

while finer spherical cementite particles are homogeneously

dispersed inside the matrix grains. In particular, the cementite

particles on the (sub) boundaries may play an important

role in retarding the grain migration through their pinning

effect during tempering and tempforming. The average aspect

ratios of cementite particles were measured to be about

1.3 inside the grains and 1.5 on the (sub) grain boundaries, respectively. The average lengths of the long axis for the cementite

particles inside the grains and on the (sub) boundaries

in tempforming at 500°C are 28 and 64 nm, respectively,

and increased to 177 and 370 nm in tempforming at

700°C. It appears that the number of cementite particles inside

the grains tends to decrease with increasing tempforming

temperature. When compared at the same tempering

temperature, there is no significant difference in the cementite

particle size distribution between the QT and TF samples.

This indicates that such bimodal distributions for the

cementite particles in the TF samples might be inherited

from those of prior tempered martensitic structures.

Links: No data

Reference: Not shown in this demo version.