Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

M23(C,B)6 carbides in microalloyed constructional steel

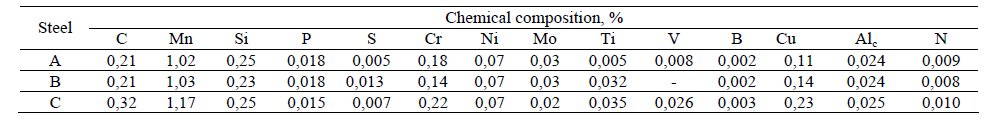

Table 1: Chemical composition of tested steels (weight %).

Table 2: Results of the mechanical properties and hardenability of the investigated steels.

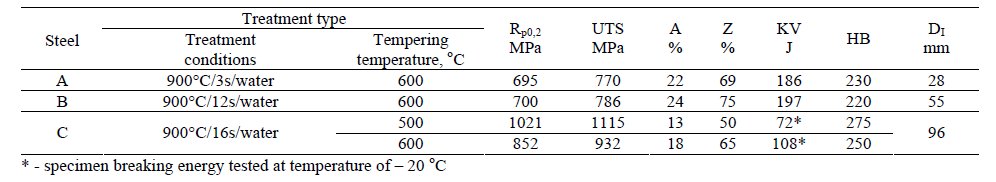

Figure 1: Fine-grained structure of the statically recrystallized

austenite; finishing forging temperature 900°C; isothermal

holding time 12s; steel B. Scale bar: 50 µm.

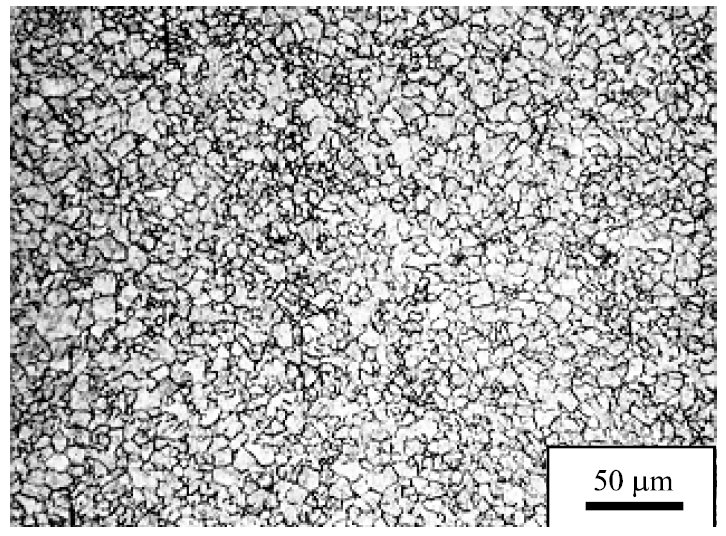

Figure 2: Fine-grained structure of the statically recrystallized

austenite; finishing forging temperature 900°C; isothermal

holding time 16s; steel C. Scale bar: 10 µm.

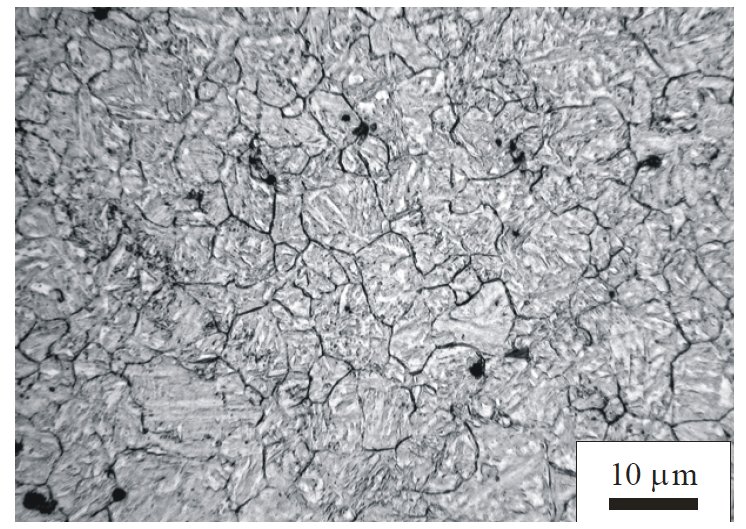

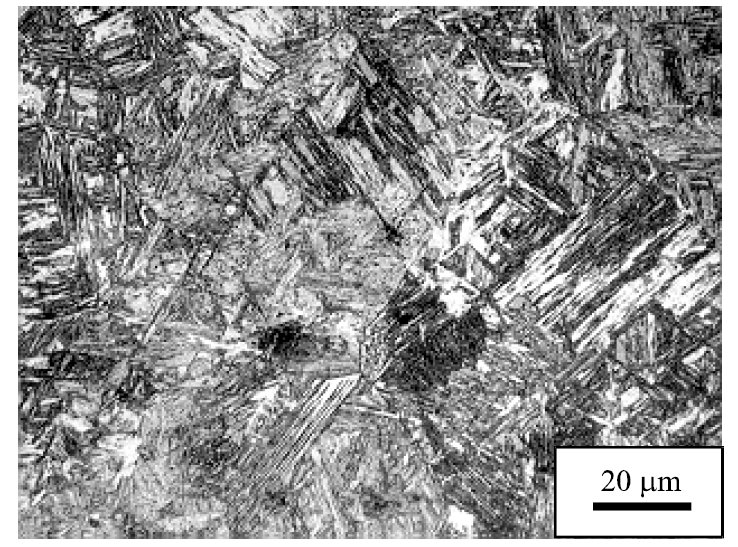

Figure 3: Martensitic-bainitic structure of steel B water quenched

from a finishing hot working temperature of 900°C after holding

for 12s. Scale bar: 20 µm.

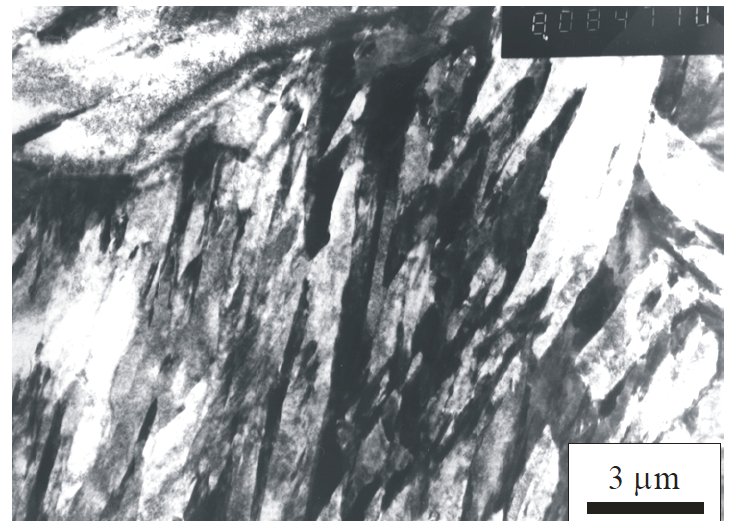

Figure 4: Lath martensite structure of steel C quenched from a

finishing hot working temperature of 900°C after holding for 16s. Scale bar: 3 µm.

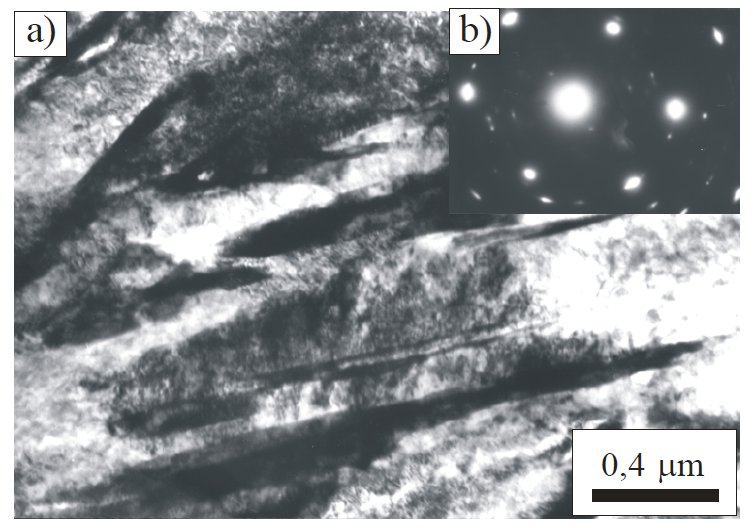

Figure 5: Lath martensite structure with the dispersive Fe3C

precipitations (steel C): a – light field, b – diffraction pattern to Fig. 5a [111]Fe-alpha and [012]Fe3C. Scale bar: 0.4 µm.

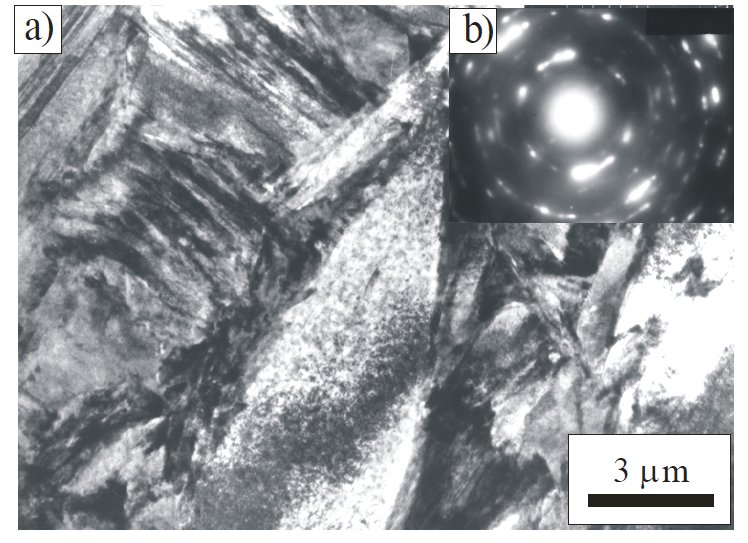

Figure 6: Dispersive M23(C,B)6 precipitations at the grain

boundaries of the primary austenite (steel C); a – light field, b –

diffraction pattern to Fig. 6a [111]Fe-alpha and [001]M23(C,B)6. Scale bar: 3 µm.

Carbide name: M23(C,B)6

Record No.: 1108

Carbide formula: M23(C,B)6

Carbide type: M23C6

Carbide composition in weight %: No data

Image type: LM, TEM

Steel name: Structural steel

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: No data

Other designation: No data

Steel group: Microalloyed constructional steels

Steel composition in weight %: See the table 1.

Heat treatment/condition: The goal of this experiment is a structure and mechanical

properties of forged elements using thermo-mechanical treatment,

made from C-Mn steel with micro-additions of Ti, V, B and N

(table 1) melted using: after furnace treatment of metal bath, and

continuous casting ingots with intersection 100..100 mm. Ingots

after their solidifications were adjustly rolled for bars with a

dimention about 36 mm, and after using the same conditions for bars

with dimention of 17 mm. The range of adjusted rolling temperature

were taken basing on calculation of solubility in the austenite microadditions added to the steel.

Note: Purpose: Effect of the thermo-mechanical treatment conditions on the structure and mechanical properties of

the forged elements of constructional C-Mn steels with Ti, V, B and N microadditions.

Design/methodology/approach: Metallography, electron microscopy, tensile test, hardness measurements,

hardenability calculations, Charpy-V tests have been used.

Findings: The thermo-mechanical treatment allows to obtain the fine-grained austenite structure during hot

plastic deformation, and gives forged elements obtaining: yield point Rp0,2 over 690 MPa, UTS over 770 MPa,

hardness 220 up to 250 HB and breaking energy KV over 180J after high tempering.

Research limitations/implications: It is predicted TEM investigations on structure of the forged elements after

thermo-mechanical treatment.

Practical implications: Investigations carried out showed full usability of micro-alloyed steels for producing

forged machine parts with the high strength and cracking resistance, using the energy-saving thermo-mechanical

treatment method.

Originality/value: Production conditions of energy-saving thermo-mechanical treatment of forged elements of

HSLA constructional steels – with the diversified hardenability, were presented.

Thermo-mechanical treatment was realized thanks to open die

forging of experimental segments with 17 mm diameter and 150

mm length in the temperature range of 950 to 900°C and 1000 to

900 C - respectively from steel A and B type to rods with

intersection 12 x 12 mm. Before quenching in water these rods

were hold at a temperature of end forging for 3 and 12s.

Quenched rods were tempered at a temperature of 600°C for 1h.

Whereas rod segments from steel type C with intersection 24 x 24

mm were forged in a range of temperature from 1150 up to 900 C to the shape of rods of intersection 12 x 12 mm. Before

quenching in water the rods were hold in a temperature of end

forging for 16s, and after were tempered in temperature of 500

and 600 C for 1h.

Investigations showed that examinated steels after thermomechanical

treatment and after quenching have a fine-grain

structure of primary austenite (fig. 1, 2) with a grain size about

10, 5 and 8 and martensitic-bainitic structure (fig. 3) and hardness

42, 44 and 49 HRC – respectively for a steel A, B and C type.

Hardness of the steels is decreasing after high tempering from

220 to 250 HB, which not create difficulties, during mechanical

treatment of forged elements.

Examinations of the structure of thin foils made in TEM

(transmission electron microscope) showed that steel C type

(quenched from a temperature of end forging – 900 C and hold

before that in this temperature for 16s) have lath martensite

structure (fig. 4). Inside of martensite laths it was approved a

presence of dispersive particles of cementite (fig. 5), whereas at

the boundaries of primary austenite M23(C,B)6 type dispersive

particles were found (fig. 6), which have occure in a steel during

self tempering process.

Links: No data

Reference: Not shown in this demo version.