Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Carbides in DC01EK and DC04EK low carbon steels

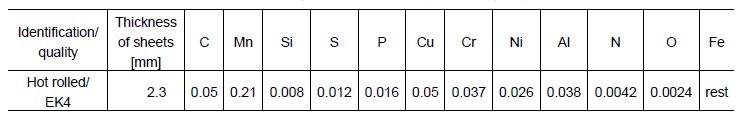

Table 1: The chemical composition of the hot rolled sheet.

Table 2: The chemical composition of the annealed sheets.

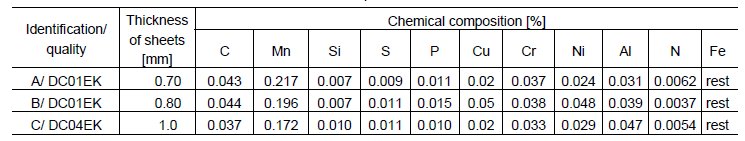

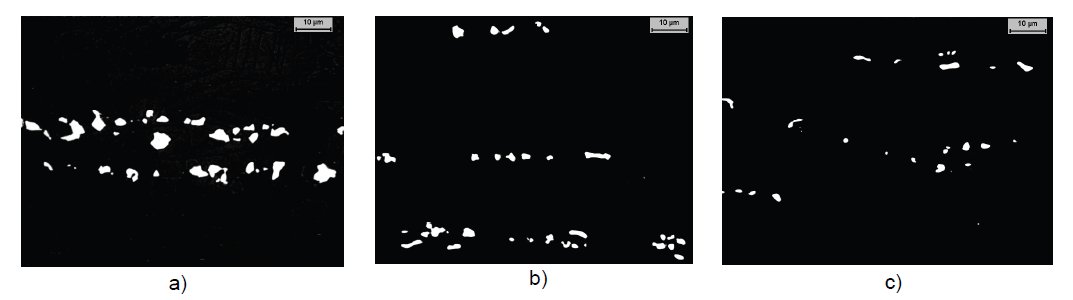

Figure 1: Carbides morphologies after different thickness reduction. Micrographs parallel with the rolling surfaces

a)12% b)37% c)51% d)69%. Scale bars: 10 µm.

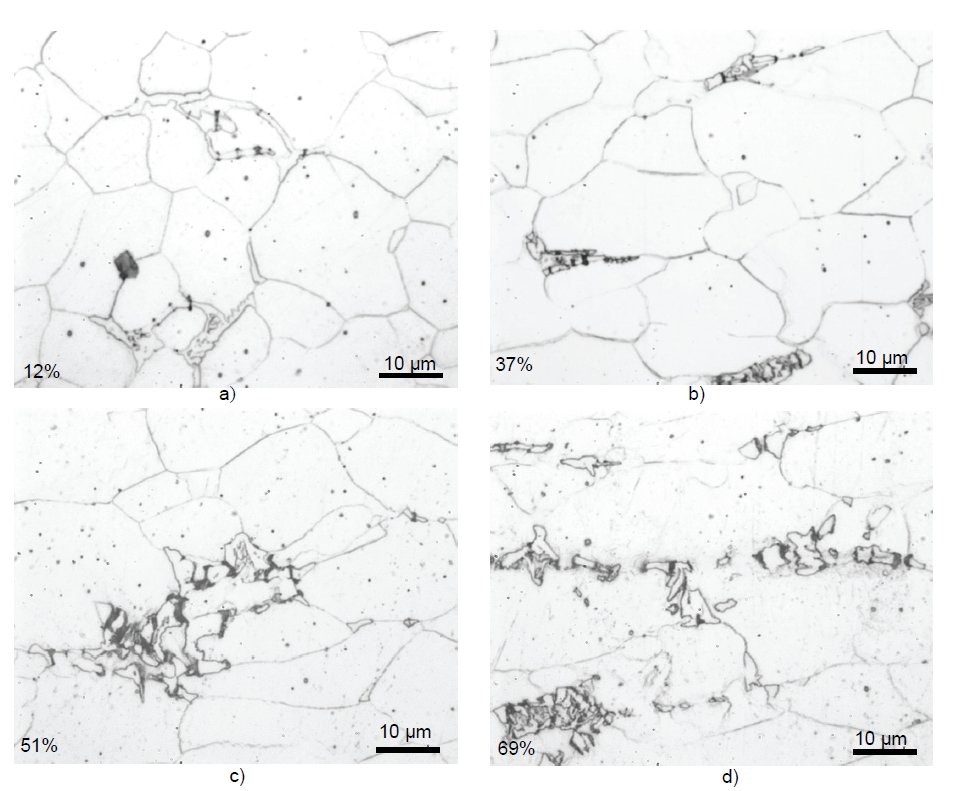

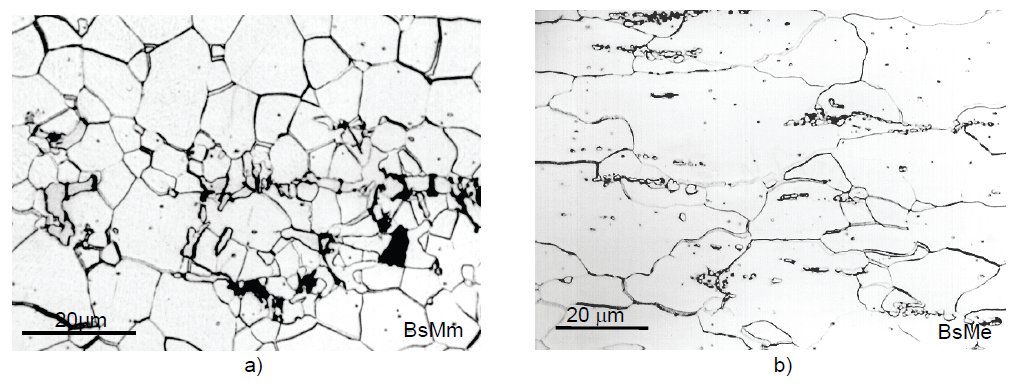

Figure 2: Microstructures of samples in rolling direction after some characteristic reduction level

a)25% b)31% c)60% d)71%. Scale bars: 20 µm.

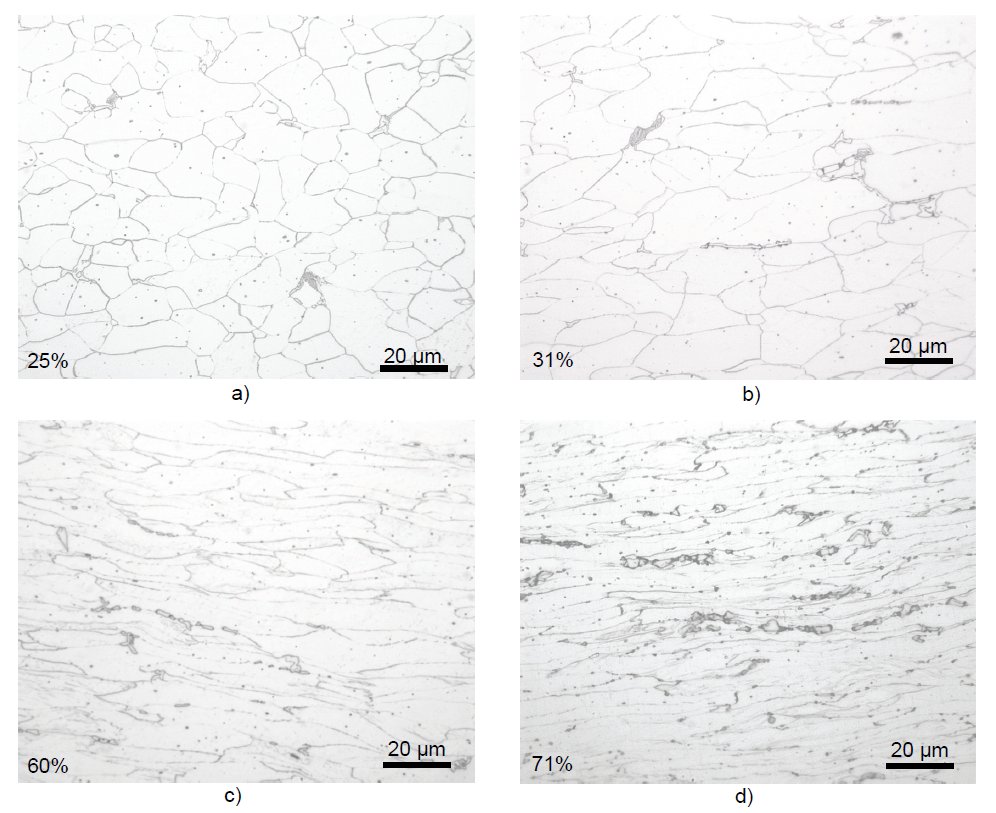

Figure 3: Micrographs parallel with surface

a) middle of the coil middle of the strip b) end of the coil, middle of the strip. Scale bars: 20 µm.

Figure 4: Carbides morphology on longitudinal section; Klemm’I

a) AaMm; b) AaEm; c) AaEe.

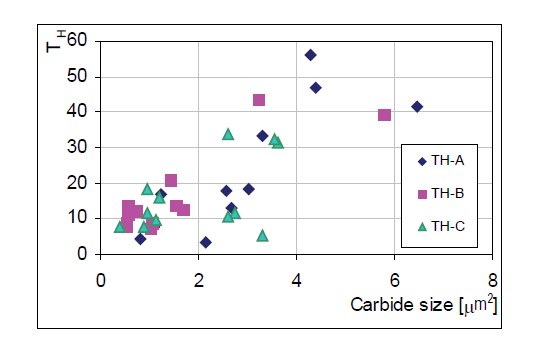

Figure 5: The carbide size effect on TH values.

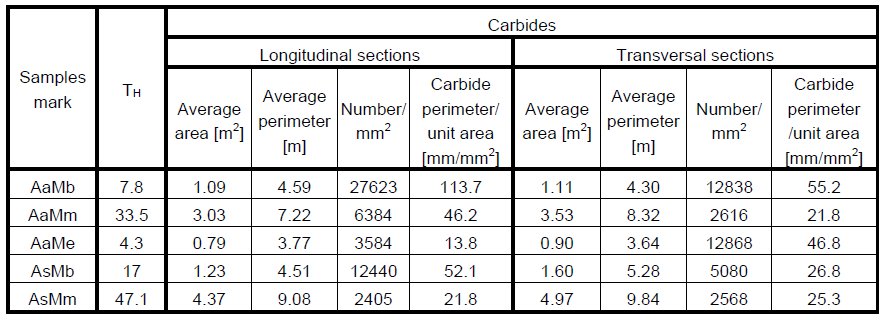

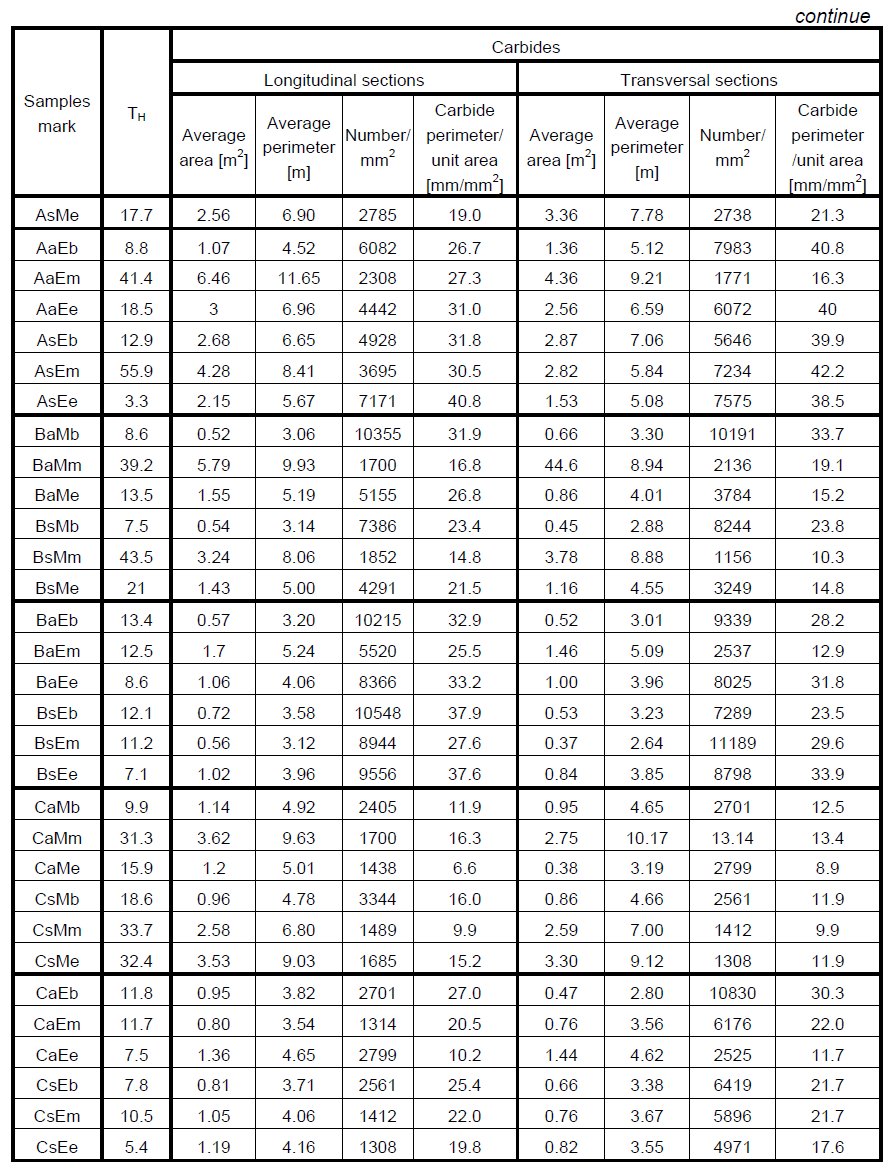

Tabble 3: Characteristics of samples regarding the carbides and TH values.

Carbide name: No data

Record No.: 1216

Carbide formula: No data

Carbide type: No data

Carbide composition in weight %: No data

Image type: LM

Steel name: DC01EK and DC04EK

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: No data

Other designation: No data

Steel group: Low carbon steels

Steel composition in weight %: See the tables 1 and 2.

Heat treatment/condition: In our experiments we have studied the hydrogen permeability and the microstructure at different

deformation levels (cold rolling) of Al-killed low carbon enamel-grade steel sheets. The steel were

elaborated in LD steel converter, followed by continuous casting, hot rolling and pickling at

Steelworks in DUNAFERR Ltd. The coiling temperatures were high (exceed 700°C), so we expected

for the hot rolled strip the appearance of carbides at the ferrite grains boundaries.

The effect of the plastic deformation on the microstructures and the hydrogen permeability have

been studied one steel sheet samples cold rolled on several rolling levels by duo rolling mill in

Laboratory at Budapest University of Technology and Economics, Department of Material Science

and Engineering. The chemical composition of the steel is given in Table 1.

To study the ferrite grain size and the carbide morphology effects on the hydrogen permeability of

Al-killed, unalloyed low carbon steel sheets were examined samples from different parts of three

cold rolled coils prepared for enamelling. The steel sheets qualities were DC01EK and DC04EK

(EN 10209 - 96). The chemical composition of the coils is given in Table 2.

Each of the examined coils was elaborated in LD steel converter, followed by continuous casting, hot

rolling and pickling at Dunaferr Steelworks Ltd. The coils were cold rolled at Dunaferr-Voest Alpine

Ltd. For the cold rolled sheets the thicknesses reduction was about 70%. After cold rolling the

examined coils were annealed in gutter-wound coil, in bell-type annealing furnace. The annealing

temperature was 670°C; the holding time in each case was 16 hours. The annealing was succeeded

by skin-pass rolling.

The carbides morphologies were determined applying Quantimet 550 image analyser at the

Innovation Management of Dunaferr Co.

Note: The tendency for fish-scale formation in case of the cold rolled Al-killed low carbon enamel grade steel

sheets has been characterized by the hydrogen permeability. There are a good correlation between the

microstructure and the hydrogen permeation time. The cold rolling effect on the microstructure and on the TH value

have been studied on samples prepared from Al-killed low carbon steel sheets with high coiling temperatures after

several cold rolling levels. The microstructure of the hot rolled sheet was formed from ferrite and large carbides. The

TH value of the hot rolled strip was very short. Due to the cold rolling at the beginning of the process the dislocation

densities increase. After some % of reducing in thickness at the ferrite –carbide interfaces appear voids. Increasing

the reduction in thickness cracks appears in the carbides. After heavy reductions the carbides are broken into

fragments, groups of fragments being elongated in the rolling direction. Increasing the reducing grade of the sheets’

thickness the hydrogen permeation time calculated for 1 mm thickness increased. After some reduction level the TH

value increased significant. At these reduction levels in each case something has changed in the microstructure

characteristics. Serve as an example at about 31% reduction TH =4.04 min/mm2; at 37% reduction TH =11.56

min/mm2. There we could observe broken carbides and microcavities between them. At 51% reduction for the

microstructure has became characteristic the broken carbides, TH =24.4 min/mm2. Other jumping were observed at

60% reduction (TH =47.9 min/mm2) where the ferrite grains elongation became characteristic.

Plastic deformation effect: We have studied the effect of the cold rolling on the

hydrogen permeation time calculated for united steel

sheet thickness and on the microstructure. We studied

the microstructure of the samples on longitudinal,

transversal cross sections and parallel to the surface.

The microstructures of the hot rolled strips were

homogeneous, formed from ferrite, carbides, few

pearlite and non-metallic inclusions. The carbides and

pearlite were located at the equi -axial ferrite grains

boundaries. The equi -axial ferrite grain size was

dgen=26.6 µm. The hydrogen permeation times were

very short (TH = 0.6). Increasing the reduction of the

thickness of the sheets the hydrogen transmission time

increased, but at some reductions of the thickness

appeared jumping in the TH value. At 12%

reduction in comparison with hot rolled strip the

microstructure has not changed, but at few places it

could be discovered cracks in the carbides (Fig. 1). At 18%- 20% reduction of the thickness we could discern 1-2 broken carbides. After a reduction about25% we could observe more but not too much broken carbides. The cracks appeared perpendicular

on rolling direction and on the surface. Sometimes we observed microcavities in ferrite closed by the

broken-points. Sometimes cracks in carbide are not observed by microscope, but voids appeared at

the ferrite–carbide interface. The equi -axial ferrite grain size was dgen=26.6 µm. After 31% reduction

of the thickness we observed a moderate ferrite grain elongation in longitudinal direction (Fig. 2a.).

At 37% reduction appeared a sharp incresing in TH value (TH =11.56). There we could discern more

broken carbides and between the carbide fragments microcavities have appeared.

Increasing the reduction of the thickness the ferrite grains extension in rolling direction became

progressively more apparent (Fig. 2). The hydrogen permeation time increased significantly (TH

=24.4) after 51% thickness reduction. The broken carbides became characteristic after 51%

thickness reducing. Microcavities appeared among the carbide fragments. At 60% reduction the

hydrogen permeation time approximately had doubled (TH =47.9). At these samples near the broken

carbides the ferrite grain elongation became characteristic. At about 70% reductions the carbides

were broken into fragments and the groups of fragments were elongated in the rolling direction. The

ferrite grains elongation became more visible. For the last 3 reductions levels on the longitudinal

samples has became visible shear bands. The calculated hydrogen permeation time was 101.

Presence of microcavities plays important role to avoid the fish scale formation. If they are present in

big amount they not disappeared during annealing and during enamel firing thermal cycle.

Effect of carbides and ferrite grain sizes were studied on Al-killed low carbon enamel grade steel

sheets after annealing under industrial condition. The thicknesses reductions of the sheets during of

the cold rolling were about 70%.

In order to study the microstructure the samples were prepared from the beginning (samples

notification: b), from the middle (samples notification: m) and from the end of the coils (samples

notification: e) 2.2 m long sheets before and after skin-pass rolling. The samples were taken from

the middle transversal strips of the sheets, and they are nominated with a after annealing and with s

after skin-pass rolling.

TH values were measured prior to and after skin-pass rolling at the beginning, in the middles and at

the end of the coils. We have measured the hydrogen permeability in each case in the middle

(samples notification: M) and at the edges (samples notification: E) of the transversal bands of

sheets (3 samples in each positions). The TH values of the samples taken from the middle of cold

rolled coils, and from the middle of the transversal strips were long; but generally the TH values of

samples taken from the end or from the beginning of the coils, were much lower.

The microstructures of the samples were formed from ferrite, carbides and non-metallic inclusions.

The microstructures of the cold rolled sheets were not homogeneous. There were differences in the

microstructure between the middle of sheets and at the edges of sheets, and middle of the coils and

at beginnings and at the ends. The differences are likely to be caused by the technology. During hot

rolling the temperature is different in the middle and at edges of coils. The microstructures at the

beginning of the coils and at the end of the coils due to the manipulation, differ from the

microstructure in the middle of the coils. Annealing in gutter-wound coil in bell-type furnace also

influences the microstructure.

The carbides groups were generally smaller in the middle of the coils and at the edge of the sheets

than in the middle of the sheets (Fig. 3). The microcavities were smaller, or eventually disappeared. At the

samples taken from the end and from the beginning of the coils the carbides were generally relative

small and have round shape. Microcavities were not characteristic among the carbides. To study the carbide morphology the samples were etched by Klemm’I reagent (Fig. 4). The broken carbides areas typically were higher than 3 µm2 in the middle of the coils and in the

middle of the sheets. In the middle of the coils and at the edge of the sheets the carbides groups

were generally smaller than in the middle of the sheets. The carbides areas of the sheets with 1 mm

thickness (C) were between 2-3 µm2, while for sheets with 0.8 mm thickness (B) were between 1-2

µm2 and for the sheets with 0.7 mm thickness (A) were between 4-7 µm2.

Characteristics of samples regarding the carbides are given in table 3.

Links: No data

Reference: Not shown in this demo version.