Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Kappa carbides in Fe-(4 6)Mn-(6 8)Al-0.3C steel

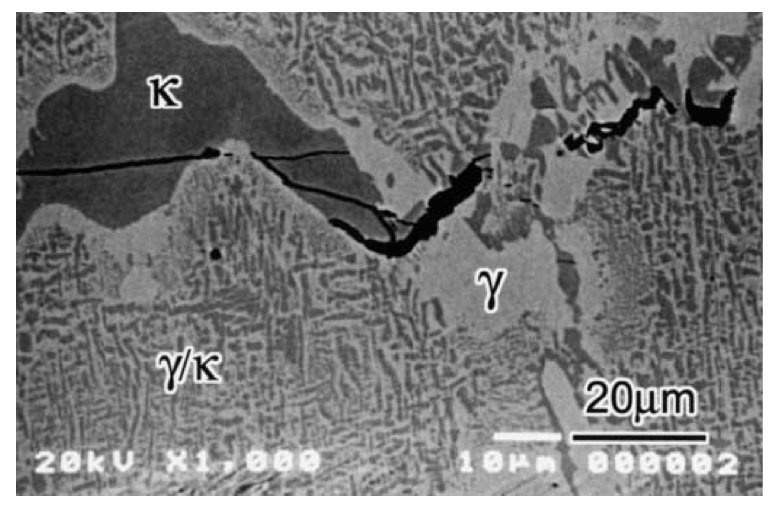

Figure 1: A back-scattered electron image of the tensile specimen in

the vicinity of fracture surface of the Fe-29Mn-9Al-2.6C (in mass%) alloy

(Kimura et al., 2004). Scale bar: 20 µm.

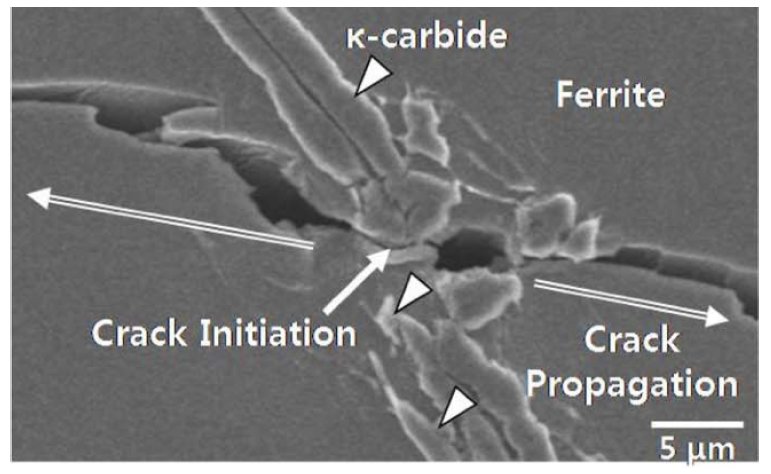

Figure 2: Scanning Electron Microscope (SEM) micrographs of the crosssectional

area beneath the tensile fracture surface of the Fe-(4 6)Mn-(6 8)Al-

0.1C (mass%) alloy. Crack was initiated in kappa-carbide and rapidly propagated

into ferrite (Han et al., 2010). Scale bar: 5 µm.

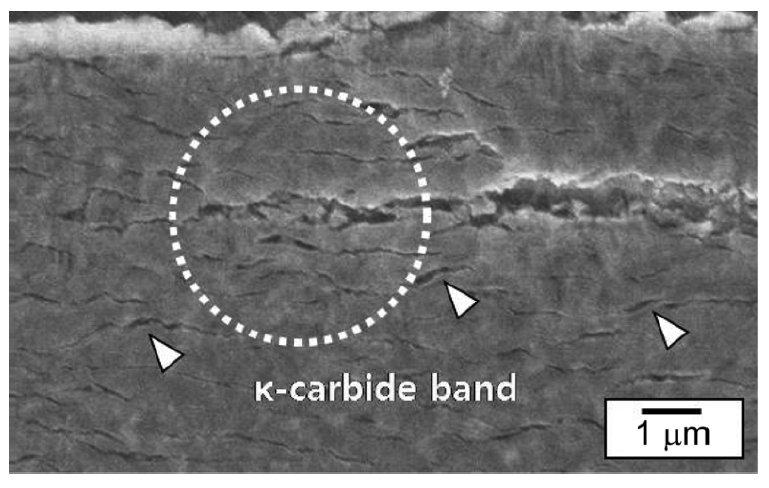

Figure 3: SEM micrographs of the cross-sectional area beneath the tensile

fracture surface of the Fe-(4 6)Mn-(6 8)Al-0.3C (mass%) alloy. Crack in

the kappa-carbide band is short and discrete (Han et al., 2010). Scale bar: 1 µm.

Carbide name: Kappa carbide

Record No.: 1232

Carbide formula: (Fe,Mn)3AlC

Carbide type: No data

Carbide composition in weight %: No data

Image type: SEM

Steel name: Fe-(4 6)Mn-(6 8)Al-0.3C

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: No data

Other designation: No data

Steel group: High manganese and high aluminum steels

Steel composition in weight %: Fe-29Mn-9Al-2.6C

Heat treatment/condition: No data

Note: (Fe,Mn)3AlC kappa-carbides are important substance in high strength

light-weight steels. Kappa-carbide is known to initiate crack and propagate

the crack or, otherwise, pin the slips and make uniform shear

bands. These opposite properties was decided by environment of the

system. Therefore phase diagram of Fe-Mn-Al-C quaternary system

and kappa-carbide is vital for this kind of steels. However, there is no

solid thermodynamic value and stability of kappa-carbide. To work towards

this goal, the all-electron full potential linearized augmented

plane-wave method(FLAPW) was used within the generalized gradient

approximation. The formation enthalpies of various kappa-carbides are

calculated. All of kappa-carbides have negative formation enthalpy. The

lowest kappa-carbide formation was Fe2MnAlC which is 9.5 kJ atom-mol.1

lower than the highest formation Fe3AlC. When the carbon position

was changed to another octahedral position in Fe2MnAlC, the formation

energy becomes positive but magnetic moment was increased. In

this research, first-principles calculation result was reassessed using

Monte-Carlo cell gas model. The result of Monte-Carlo simulation

showed smaller entropy value than configurational entropy caused by implementation problem. However, general temperature dependence

of free energy, entropy, specific heat and internal energy is well predicted

by simulation. In the future work, we hope to incorporate

the calculated energies in to phase diagram calculation methods and

modify cell gas model to improve implementation problem.

In general, carbide is harder than pure iron and strengthens steels. However,

it can also be brittle, therefore, it initiates cracks or helps the propagation

of cracks. Also, the phase which is surrounding kappa-carbide is important. For example,

coarsened kappa-carbide in a phase boundary can easily initiate cracks which

propagate (Fig. 1.4) when austenite (gamma) coexists with kappa (Kimura et al.,

2004). Indeed, if there is ferrite, the crack will go through the ferrite (Fig.

1.5) and non-work hardened ferrite in the kappa-carbide inhibits crack propagation

or changes the direction of crack (Fig. 1.6) (Han et al., 2010).

The experiments on fine kappa-carbide was reported by Frommeyer and Bršux

(2006). In their work, nano-size kappa-carbide was regularly distributed and

coherent with austenite and it sustained homogeneous shear band acquired

by dislocation glide. As a result, ductility is remarkably improved and the

specific energy absorption is as high as that of TWIP steels.

Scattered kappa-carbide on phase boundaries is usually the initial point of

cracks. When austenite coexists with kappa-carbide, cracks propagate along

kappa-carbide or along the boundary between kappa and austenite. However, when kappa is in ferrite, the crack rapidly moves into the ferrite. With high manganese and high aluminum contents, austenite is highly stable so phase transformation

to martensite would not happen and the stacking fault energy is

too high to induce mechanical twinning. So shear band induced plasticity

will be the primary deformation mode. Kappa-carbide sustains shear bands so,

it is possible for those to be uniformly dispersed. However, to obtain good

ductility via the SIP effect, kappa-carbide should be fine and coherent with the

austenite (Frommeyer and Bršux, 2006). It clearly is necessary to strictly

control the precipitation of kappa-carbide.

Links: No data

Reference: Not shown in this demo version.