Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Chromium carbides in 3% chromium steel for rolls

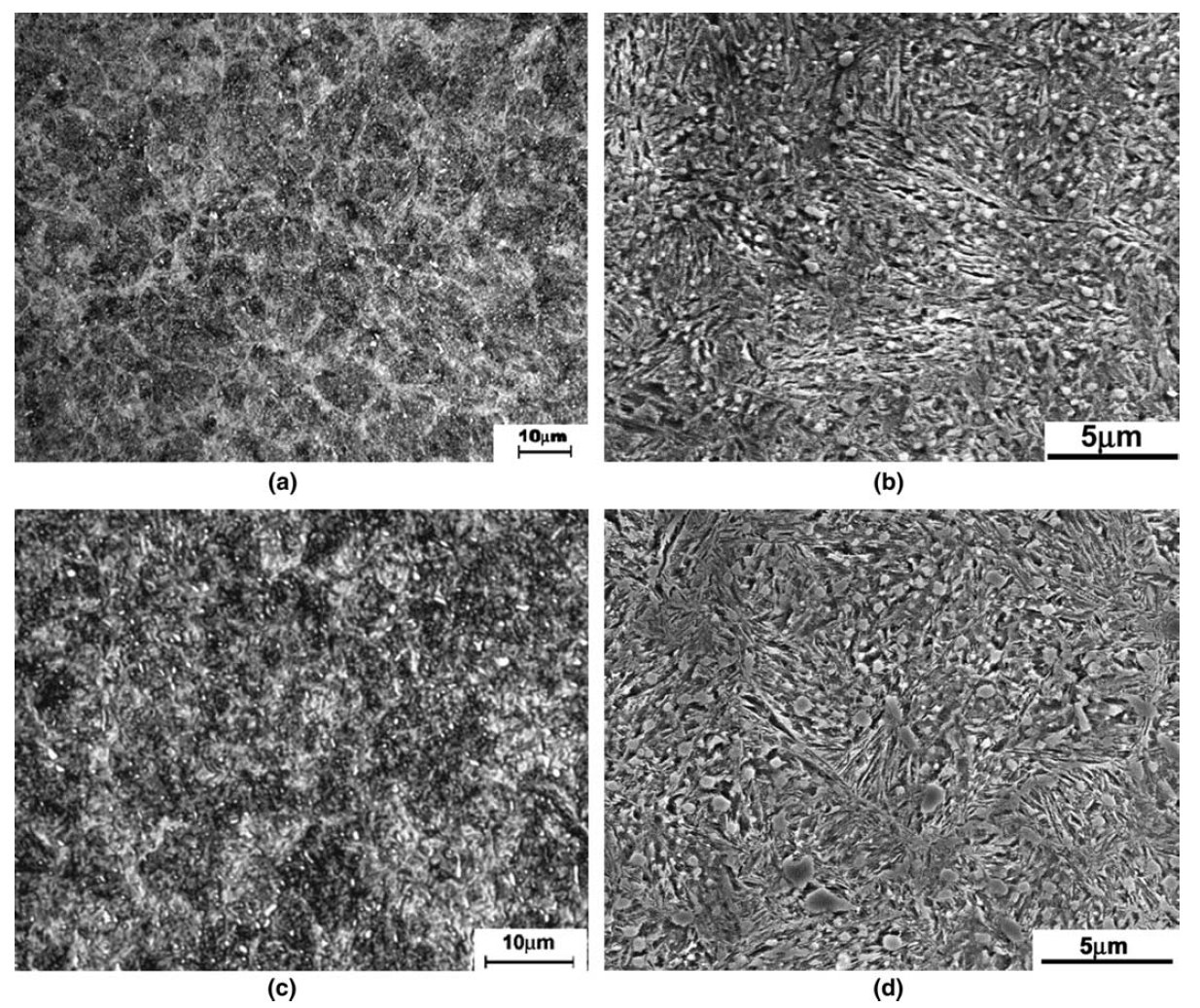

Figure 1: Radial section. Induction hardening layer. Working surface showing tempered martensite and dispersed chromium carbides.

Etching: nital: (a) and (b) microstructure of roll 1; (c) and (d) microstructure of roll 2. Scale bars: 10, 5 µm.

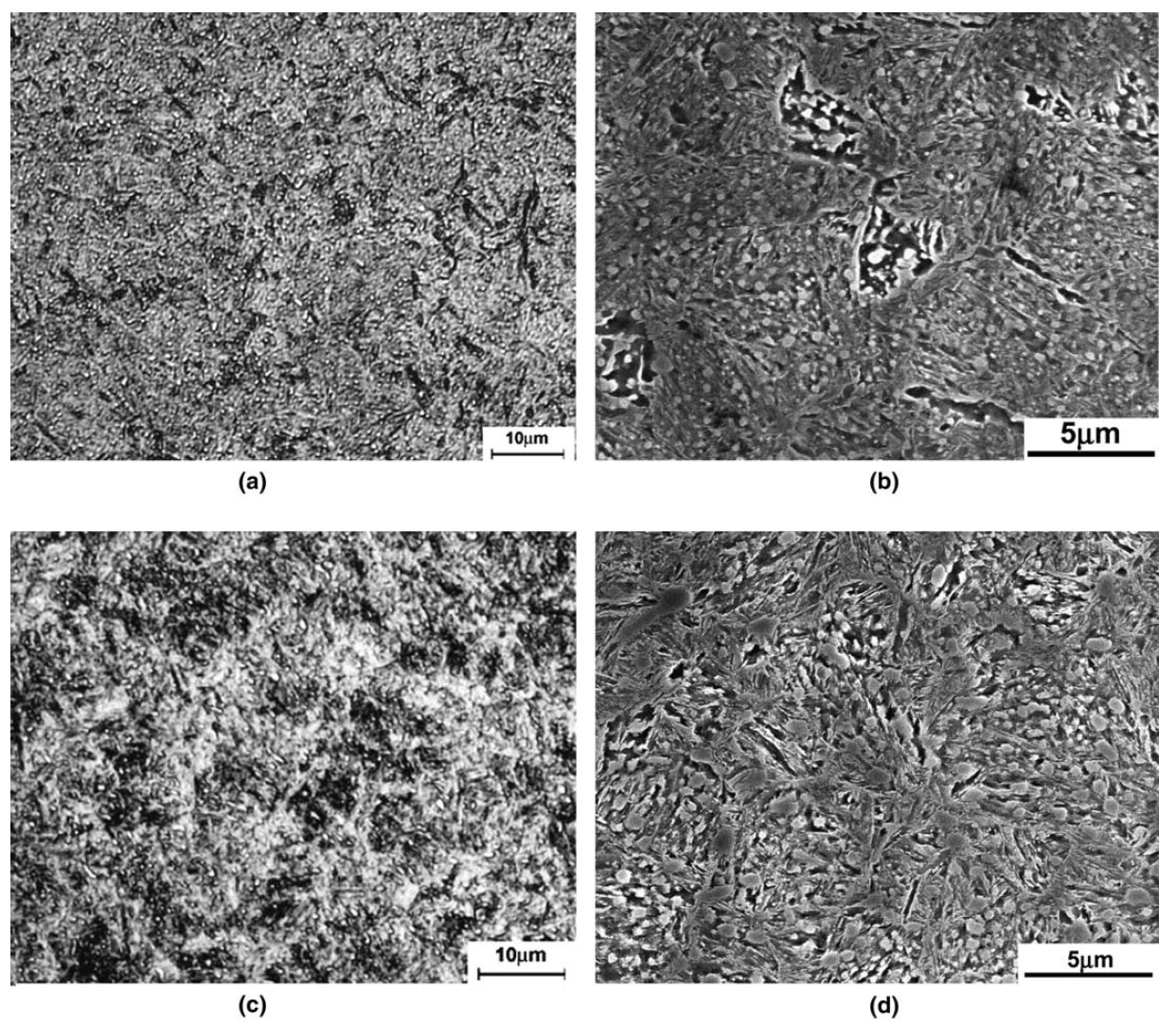

Figure 2: Radial section. Induction hardening layer. Spalling surface showing tempered martensite, dispersed chromium carbides and

spheroidised pearlite. Etching: nital. (a) and (b) microstructure of roll 1. (c) and (d) microstructure of roll 2. Scale bars: 10, 5 µm.

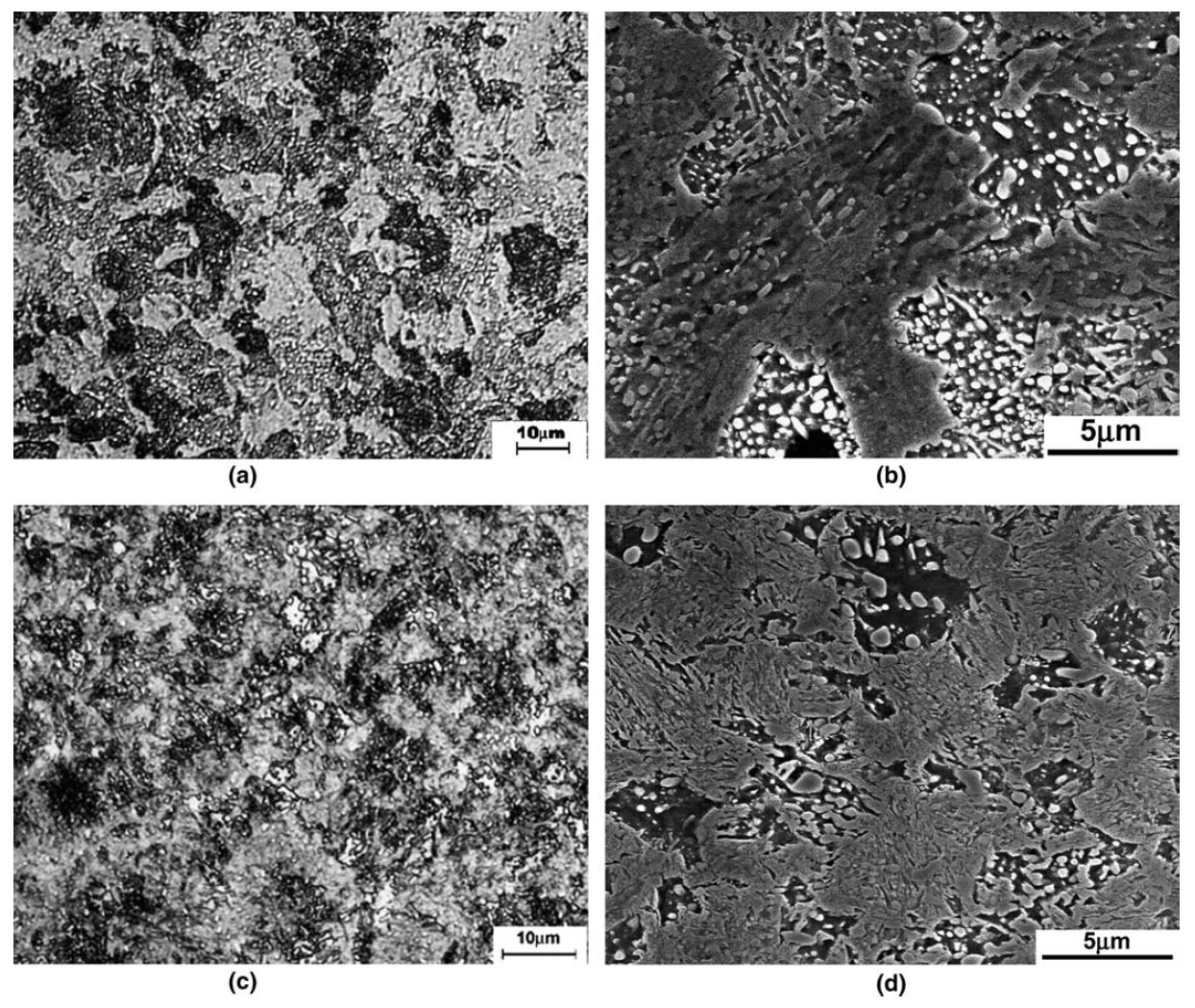

Figure 3: Radial section. Interface between the induction hardening layer and core showing tempered martensite, dispersed carbides and

spheroidised pearlite. Etching: nital. (a) and (b) microstructure of roll 1; (c) and (d) microstructure of roll 2. Scale bars: 10, 5 µm.

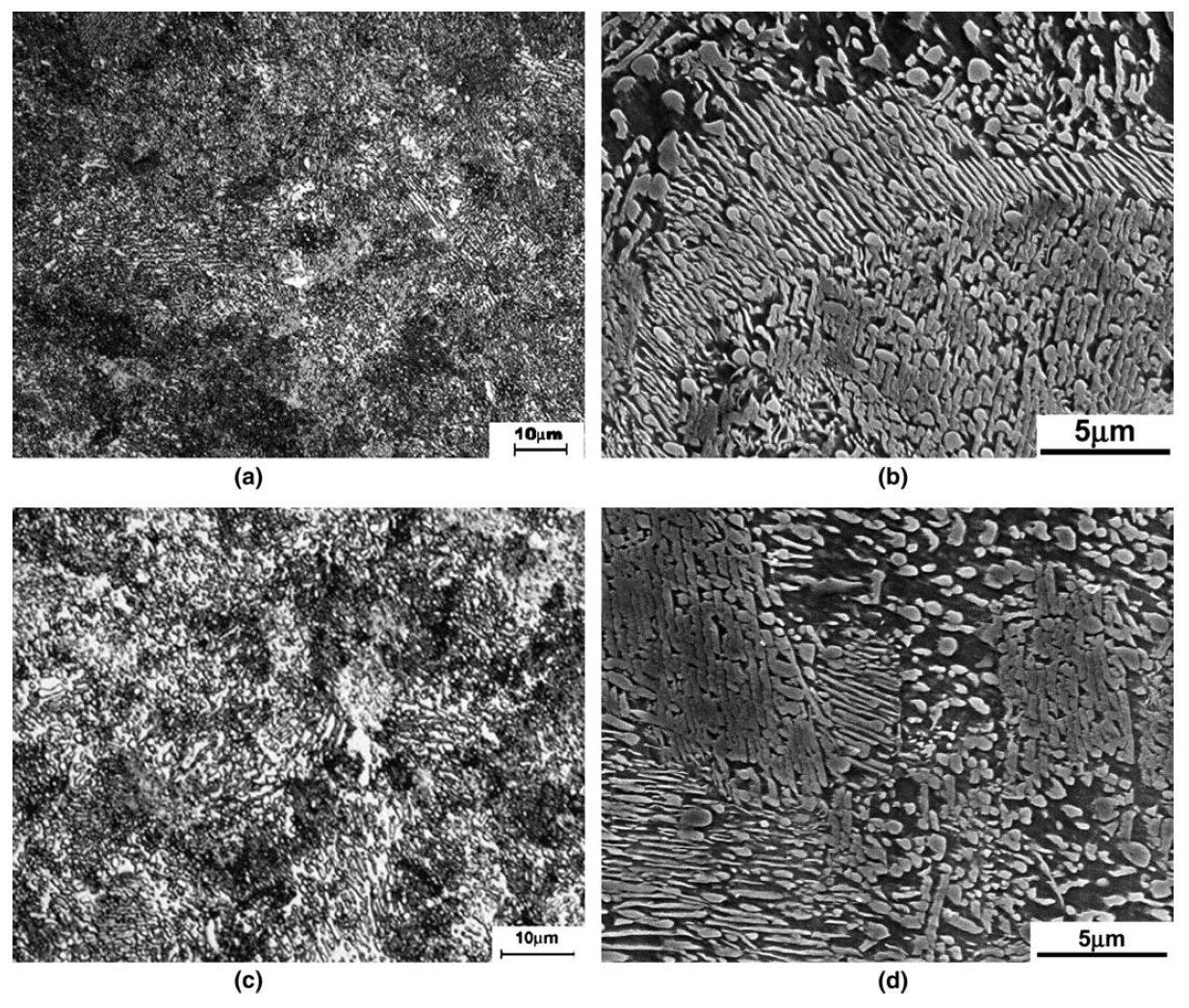

Figure 4: Radial section. Core showing ferrite and colonies of pearlite. Etching: nital. (a) and (b) microstructure of roll 1; (c) and (d)

microstructure of roll 2. Scale bars: 10, 5 µm.

Figure 5: Diffractograms – Cr-Ka emission (40 kV and 30.0 mA), continuous scan mode, scanning rate of 0.1 deg 2tehta/min, sampling pitch of

0.01 deg., sample rotation of 60 rpm: (a) Roll 2, working surface; (b) Roll 2, spalling surface.

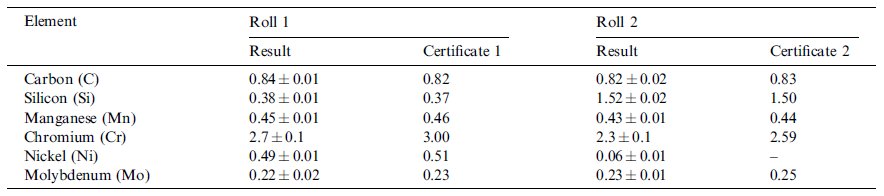

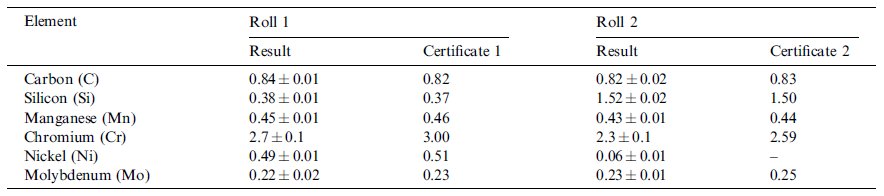

Table 1: Chemical composition in wt.%.

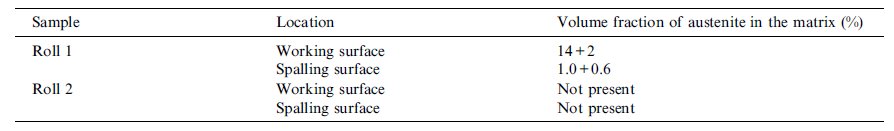

Table 2: Volume fraction of retained austenite in the matrix.

Carbide name: Chromium carbides

Record No.: 731

Carbide formula: No data

Carbide type: No data

Carbide composition in weight %: No data

Image type: LM, SEM

Steel name: 3% chromium steel

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: No data

Other designation: No data

Steel group: Cold work tool steels

Steel composition in weight %: No data

Heat treatment/condition: No data

Note: The premature failure of two forged and induction hardened low alloy steel work rolls used for cold rolling of high

and medium carbon steel was investigated. Microhardness profiles indicated that the values of the effective induction

hardening depth for both rolls are below the users requirement. Tensile testing results of the core of the rolls indicated

that the tensile and yield strengths are also below the manufacturers requirements, the latter being 50% below the

minimum requirements. The microstructure of the spalling surface presented tempered martensite, dispersed chromium

carbides and spheroidised pearlite. The presence of spheroidised pearlite may have promoted the sub-superficial nucleation

of rolling contact fatigue cracks. The heat-treatment schedule should be optimised in order to increase the

depth of the hardening layer and the mechanical properties of the core, so that the contact fatigue life of the rolls can be

improved.

The chemical composition of both rolls is in good agreement with the certificates supplied by the rolls manufacturer (see Table 1).

The inclusion content of the samples was obtained by comparison with plate I of ASTM E 45-76

standard (method A). The results indicate that the working surface and the core of the rolls present

globular alumina oxide (D type), fine series, inclusion content level 2. No information was made available

concerning the requirements for the inclusion content.

The microstructure of the working surface of roll 1 is formed of tempered martensite, approximately 1% volumetric fraction of dispersed chromium carbides

close to 0.5 µm (see Figs. 1(a–b)) and 14% volumetric fraction of retained austenite in the matrix (see Table

2 and Figs. 5(a–b)). The carbide stoichiometry could not be determined by EDS microanalysis. The microstructure

of roll 2 is similar (see Figs. 1(c–d)), but the presence of retained austenite was not observed (see Table 2).

The microstructure of the spalling surface of roll 1 is formed by tempered martensite, approximately 1%

volumetric fraction of dispersed chromium carbides of approximately 0.5 µm, 1% volumetric fraction of

retained austenite in the matrix (see Table 2), and additional presence of spheroidised pearlite (see Figs.

2(a–b)). The microstructure of roll 2 is similar (see Figs. 2(c–d)), but the presence of retained austenite was

not observed (see Table 2).

The microstructure of the transition zone of both rolls is mainly formed by spheroidised pearlite, with

the additional presence of areas of tempered martensite (see Figs. 3(a–d)). The core of both rolls is formed

mainly by pearlite (see Figs. 5(a–d)).

The presence of spheroidised pearlite (associated with low volumetric fraction of retained austenite on

the spalling surface (as observed for roll 1) is the result of the induction hardening treatment along the roll.s

depth. At a given depth, the material is not subjected to sufficient time and temperature inside the austenite

field to completely dissolve the cementite of the prior pearlitic microstructure. As a result, the carbon content of the austenite does not reach a maximum value, increasing the martensite start (Ms) and finish (Mf) temperatures and reducing the amount of retained austenite after quenching.

Links: No data

Reference: Not shown in this demo version.