Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

MC, M7C3 carbides in ROLTEC,TOUGHTEC, WEARTEC, AISI A2, D2 and D6 steels

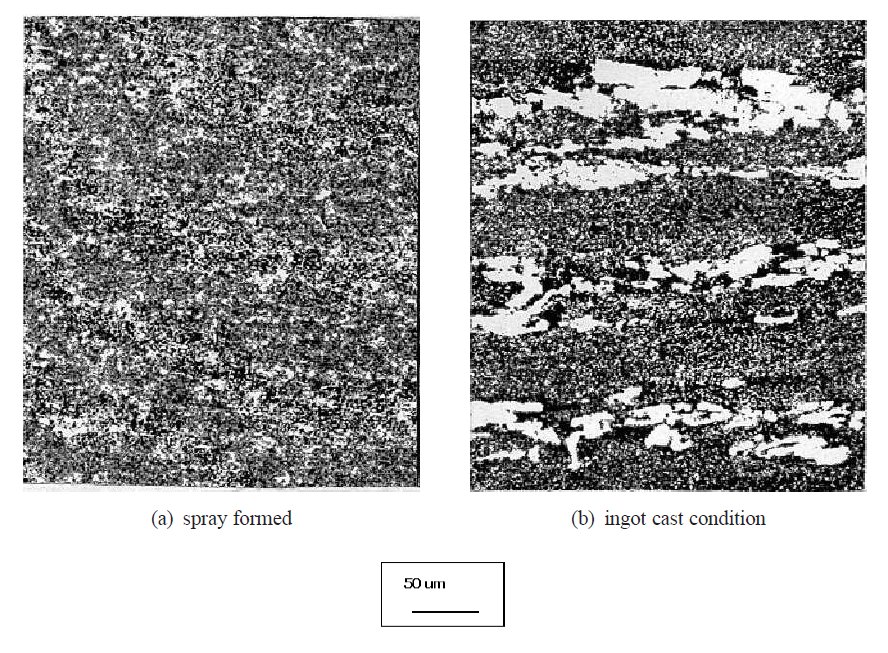

Figure 1: Microstructure of 12% Cr-steel, AISI D2. Both variants have been forged to a medium sized dimension. Scale bar: 50 µm.

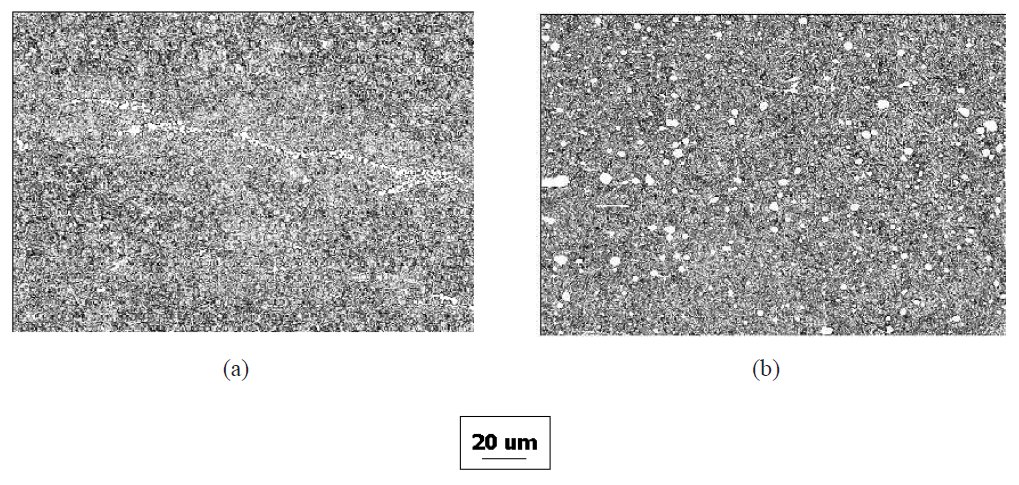

Figure 2: Microstructure of a) an ingot cast steel with 0.7% C and 5% Cr and b) a spray

formed steel alloyed with 4% V and low in Cr. Both variants have been forged to a medium

sized dimension and heat treated to 60 HRC. Scale bar: 20 µm.

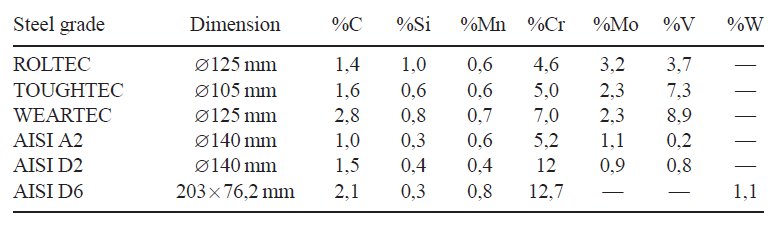

Table 1: Nominal chemical composition and dimension of investigated steel grades.

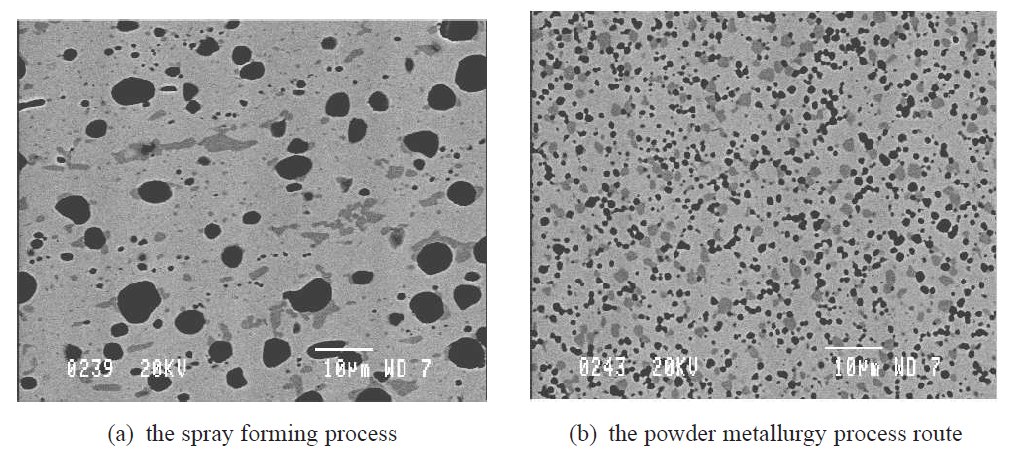

Figure 3: Microstructure of a 10% V steel after hot working to a medium sized dimension

and heat treated to 62 HRC. Scale bars: 10 µm.

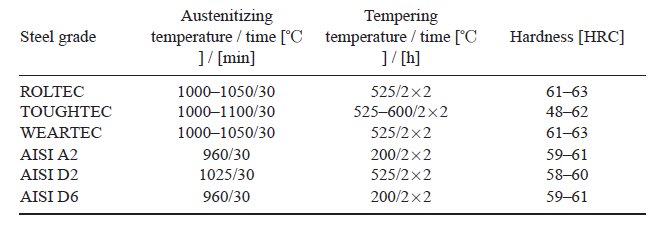

Table 2: Heat treatment procedure for the investigated steels.

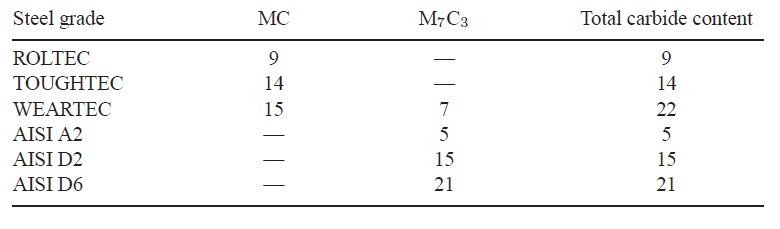

Table 3: Volume fraction (%) of carbide and carbide type after heat treatment to 55–63 HRC.

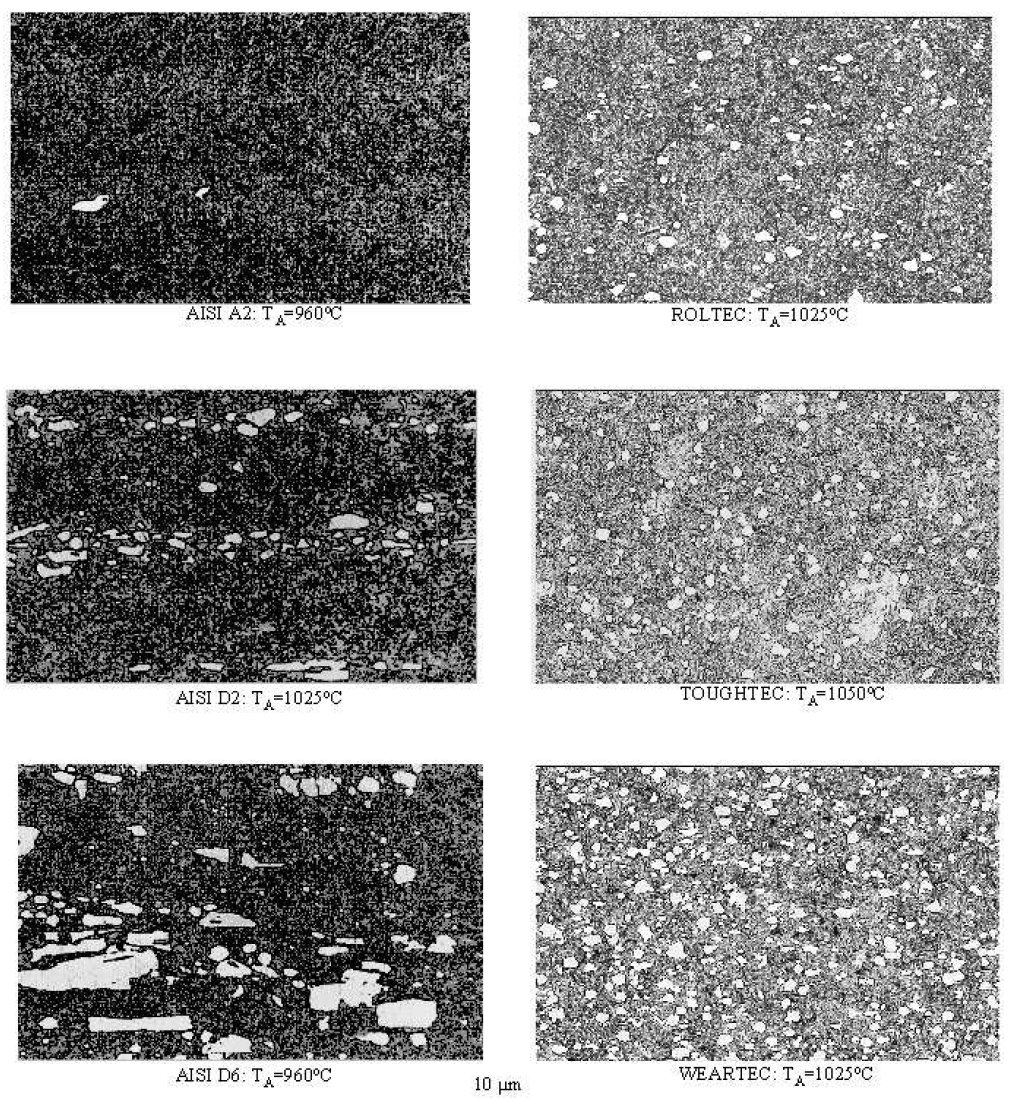

Figure 4: Microstructure of AISI A2, D2, D6, ROLTEC, TOUGHTEC and WEARTEC

in heat treated condition. Scale bar: 10 µm.

Carbide name: MC, M7C3

Record No.: 732

Carbide formula: MC, M7C3

Carbide type: MC, M7C3

Carbide composition in weight %: No data

Image type: LM, SEM

Steel name: ROLTEC,TOUGHTEC, WEARTEC, AISI A2, D2 and D6 steels

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: No data

Other designation: No data

Steel group: Cold work tool steels

Steel composition in weight %: See the table 1.

Heat treatment/condition: No data

Note: Spray forming of tool steels give unique opportunities to develop steels with

specific properties as this process allows a high degree of freedom as regards

alloying elements. Furthermore, the rapid solidification rate develops a microstructure

suitable for many tool steel applications. The manufacturing of

high alloyed tool steels with a good yield has before only been possible via

powder metallurgy, but is now also possible with use of spray forming.

Spray forming of tool steels on an industrial scale have been introduced

on a number of specially designed steel grades making use of the benefits

of the spray forming technique. The properties of the new developed spray

formed steels are unique in several aspects. Steels with high to excellent

abrasive wear resistance in combination with good ductility and a working

hardness ranging from 45–66 HRC are available. This paper presents the

properties of the spray formed tool steels produced on an industrial scale and

these are compared with conventional manufactured grades. Also, industrial

application test are presented.

Spray forming adds newopportunities to design cold work tool steels with

properties not found in conventional produced cold work tool steels. During

casting of conventional ingots the segregation of carbon and carbide forming

elements are known to give material properties in the final hot worked bar

that are strongly directional oriented and on a low level in the transverse direction. This is caused by the formation of strong carbide in segregatied

areas. Preferentially chromium carbides are formed as cold work steels are

based on high amount of carbon and chromium to obtain a properties profile

consisting of high hardness after heat treatment, adequate hardenability and

wear resistance. Ductility is due to this alloying concept and manufacturing

process a factor, which is not able to be greatly optimised. The more rapid

solidification occurring at spray forming gives less time for segregation of

carbon and alloying elements and results in lower segregation and a finer

solidification microstructure. Thus, the resulting microstructure of the hot

worked bar is more homogeneous, but nevertheless much improvement in

wear resistance and ductility can not be gained when spray forming steels of

type D2. In Fig. 1 a comparison is made of the microstructure appearance

for a 12%Cr-steel, AISI D2, manufactured via ingot casting and forging and

via spray forming followed by forging.

The conventionally manufactured Cr-alloyed steels are based entirely on

the soft chromium carbide type (M7C3; ~1700 HV), which is less advantageous

from a wear resistant point of view. The hard and wear resistant

vanadium carbide (MC; 2800 HV) is a more interesting alternative in designing

a wear resistant and ductile tool material. This concept has been

used in the development of alloys suitable for spray forming. In addition

to an excellent wear resistance the ductility is significantly increased compared

to what can be achieved via conventionally produced tool steels due to

a homogeneous distribution of relatively small carbides. Figure 2 illustrates

the uneven microstructure of chromium carbides in a martensitic matrix of

a conventional ingot cast steel with 0.7% C and 5% Cr versus the more

homogeneous microstructure of rounded vanadium and chromium carbides

of a spray formed steel with 4% V and a lower chromium content, which

promotes both wear resistance and ductility.

The properties of three commercial spray formed alloys, ROLTEC,TOUGHTEC

and WEARTEC are presented in this paper. ROLTEC and WEARTEC

are aimed for cold work applications, but also for engineering applications

where a high wear resistance is required. TOUGHTEC is regarded as a steel

aimed for plastic and hot work applications in that a higher priority is given

to ductility compared to the other two grades, but still with an excellent wear

resistance. As reference steels three conventional produced grades are used,

AISI A2, D2 and D6. Table 1 shows the nominal chemical composition and

dimension of the steels investigated. For the conventional grades the main alloying element is 5 to 12% Cr balanced with carbon to give a sufficient

hardness after heat treatment and a combination of abrasive wear resistance and ductility. The spray formed grades are alloyed with high amounts of

vanadium, 3.7–8.9% and balanced contents of chromium, 4.2–7.0% and

molybdenum, 2.3–3.2% in order to achieve a very good abrasive wear resistance

in combination with a good ductility and superior hardenabilty. This

involves that hardness can be maintained also in big section sizes after heat

treatment and/or can a lower cooling speed be used at hardening resulting

in lower dimensional changes. All conventional grades are produced in full

scale via ingot casting. The spray formed grades are manufactured as billets

with a diameter of 500 mm and a length of approximately 2 meter. The spray

forming process is described in more detail in literature.

Also higher alloyed vanadium steel grades are possible to produce via

spray forming for further hot working to suitable dimensions for various

applications. An example is given in Fig. 3, where the microstructure of

a 10% V steel manufactured via spray forming and powder metallurgy is

shown. Both production methods result in a homogeneous distribution of

mostly hard vanadium carbides in a martensitic matrix, but there is a significant difference in size of the carbides with the spray formed carbides having

an average size of around 6–10 m compared to about 2 µm for the PM

method. This microstructure difference increases abrasive wear resistance

substantionally for the spray formed steel grade, without reducing ductility

too much.

The effect of carbide size on abrasivewear resistance is illustrated inFig. 4,

where three alloys are manufactured in full scale either via conventional

ingot casting (Conv.), spray forming (SF) or powder metallurgy (PM). The

alloys have all been heat treated to 60–61 HRC. The lowest wear resistance is

shown by D2 in the whole carbide size range due to the fact that the carbides

are entirely of the softer chromium carbide type (M7C3; ~1700HV). With

an increasing amount of hard vanadium carbides (MC; 2800 HV) and an

increasing carbide size there is a significant improvement in wear resistance.

All steels have been tested as regards mechanical properties for ductility

with unnotched specimens, 7×10×55mm, and for abrasive wear resistance

with an internal standard pin-on-disc method against SiO2. Fracture toughness

testing has been performed for the spray formed grades and compared

to reference data for cold work tool steels. The steels have been heat treated

according to standard procedures to achieve a hardness between 48–64 HRC,

albeit mostly to 60–63 HRC, as shown in Table 2.

The microstructure of the spray formed grades display significant differences

compared to the conventional ingot cast steels. The spray formed

grades are characterized by an even carbide distribution with mostly hard

vanadium carbides embedded in a martensitic matrix. Depending on the alloy content the volume fraction of carbides varies between 9–20%. The

size of the carbides are typically 1–15 10 µm, whereas for D2 and D6 the carbide

size can be up to 100 µm in the longitudinal and 20 µm in transverse

direction, i.e. a significant aspect ratio of the carbide shape is present in conventionally

produced grades. Also, due to the longer solidification time at

ingot casting a heavily banded carbide structure appears in high alloyed conventional

produced steels. In Fig. 4 the microstructures of the investigated

alloys are shown after hardening and tempering.

The volume fraction of carbides in the investigated steel grades after heat

treatment generating a hardness of 58–63 HRC is presented in Table 3. Data has been determined by using the point counting technique based on SEM

pictures.

Links: No data

Reference: Not shown in this demo version.