Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Carbides in spray-formed AISI M3:2 high-speed steel

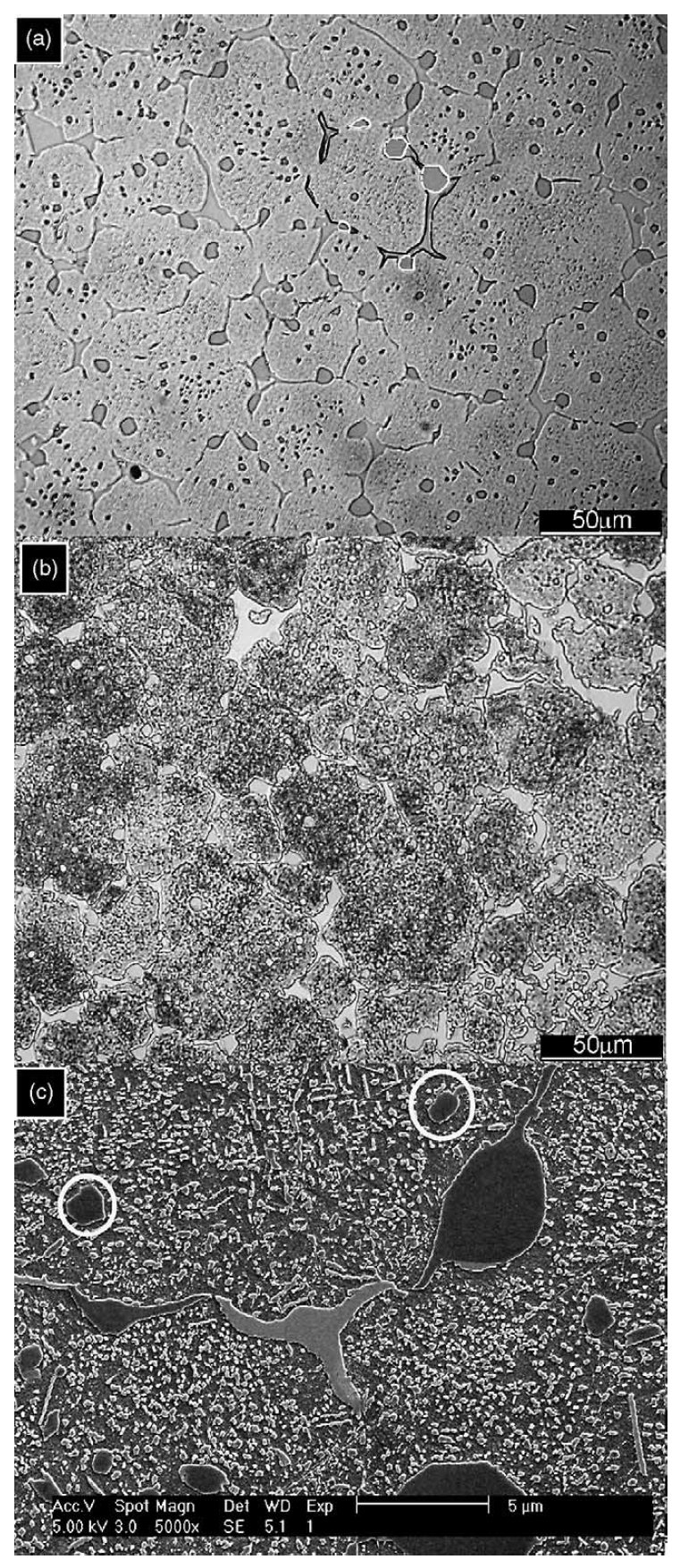

Figure 1: Microstructure of as-sprayed material (a) optical micrograph of polished

sample demonstrating the presence of a carbide network, (b) optical

micrograph of etched sample, (c) SEM image of etched sample. Scale bars: 50, 50, 5 µm.

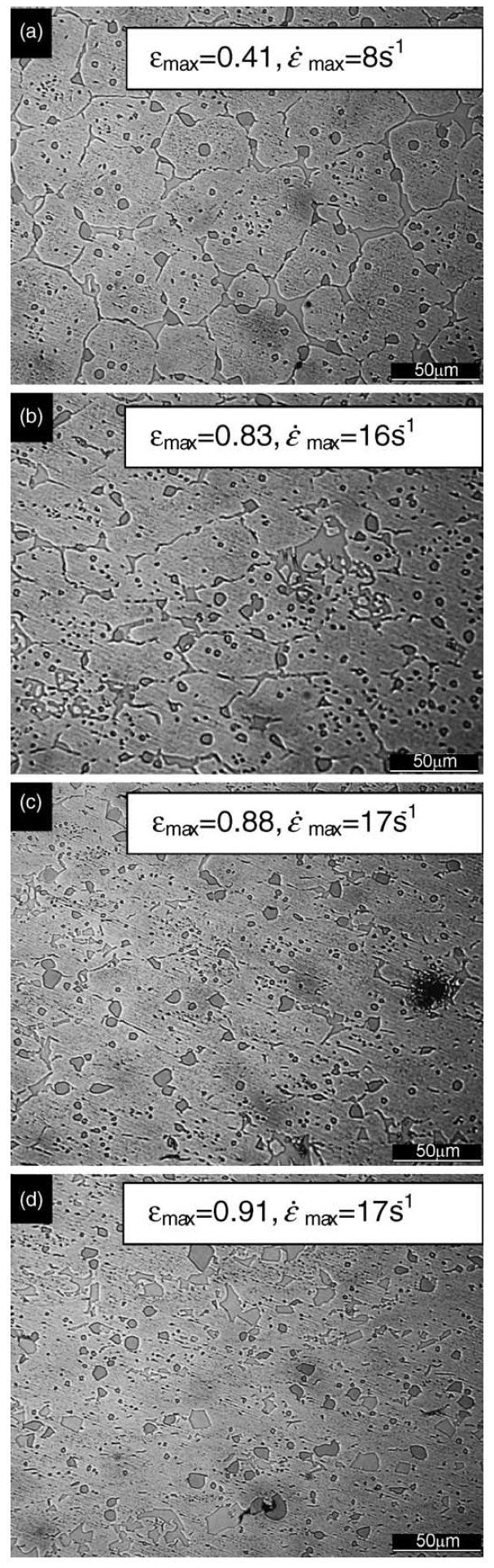

Figure 2: Series of optical micrographs along compression axis of specimen

deformed in experiment C. Positions corresponding to (a)–(d) are indicated

in Fig. 1. Scale bars: 50 µm.

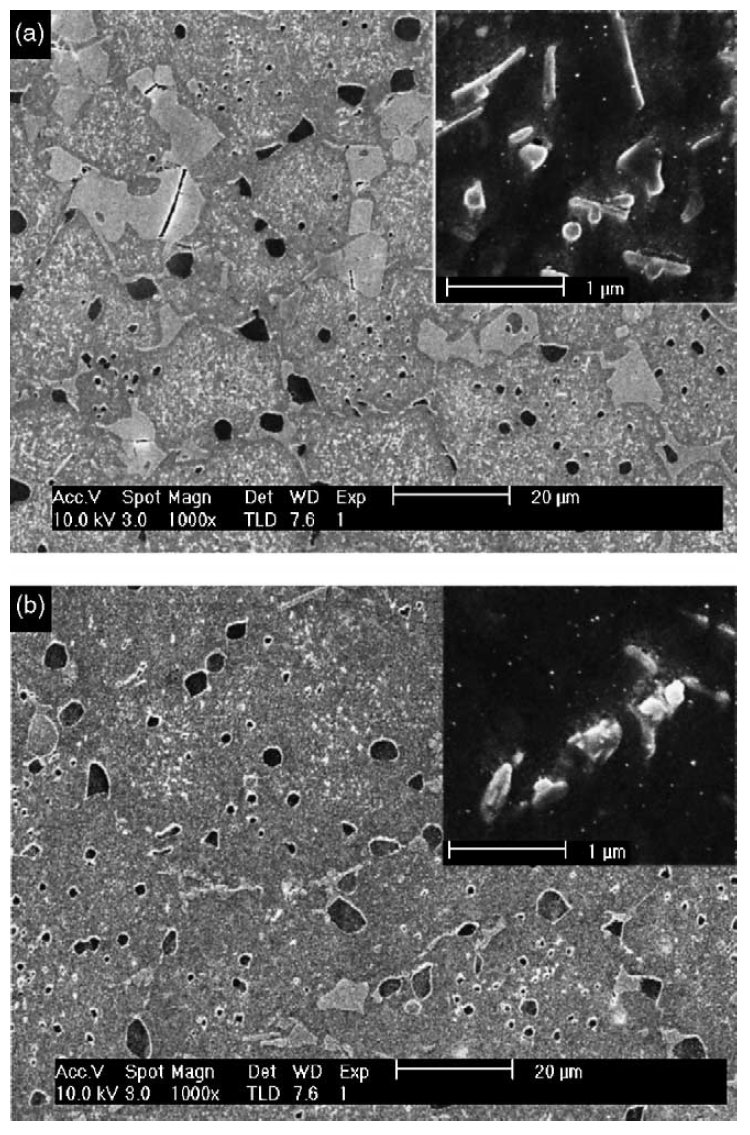

Figure 3: SEM images of cross-sections perpendicular to compression axis of

compression test samples (a) experiment B: nominal deformation temperature

900 C, (b) experiment H: nominal deformation temperature 1100 C.

Note the difference in density of submicron-sized carbides and the presence

of cracked carbides in (a). Scale bars: 20 µm.

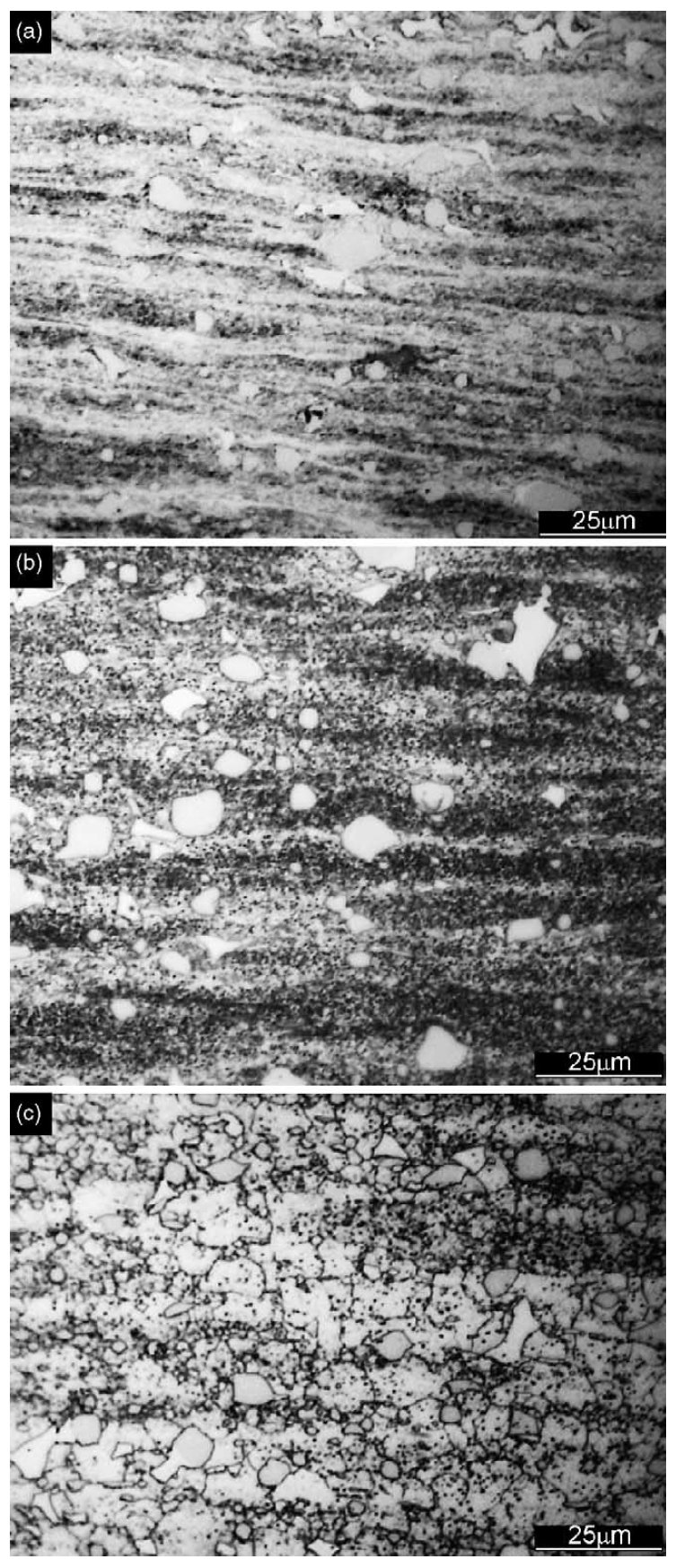

Figure 4: Optical micrographs for specimens deformed at strain rates given

and nominal temperatures T = 900 C (a), T = 1000 C (b) and T = 1100 C (c). Scale bars: 25 µm.

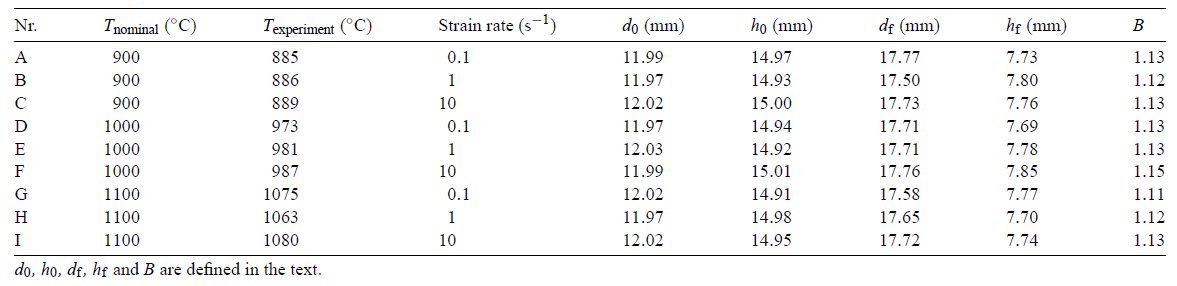

Table 1: Dimensions of specimens before and after deformation.

Carbide name: Carbides

Record No.: 733

Carbide formula: No data

Carbide type: No data

Carbide composition in weight %: No data

Image type: LM, SEM

Steel name: ASP 2024

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: AISI M3:2

Other designation: No data

Steel group: PM High speed steels

Steel composition in weight %: 1.31% C, 6.24% W, 5.34% Mo, 4.12% Cr, 3.05% V, 0.56% Si, 0.24% Mn, 0.11% Ni, 0.22% Cu, 749 ppm N.

Heat treatment/condition: A 3-ton spray-formed high-speed steel billet was supplied by Danspray (Gregersenvej 8, 2630 Taastrup, Denmark) in

the as-sprayed condition with approximate dimensions 0.5 wide by 2 m long. Axisymmetric compression tests at temperatures in

the range of 900–1100 C and strain rates between 0.1 and 10 s-1 were carried out in order to simulate the microstructure

evolution during forging. The nominal maximum strain for all experiments was 0.69, which corresponds to a reduction

of 50%. This is a typical height reduction for billets to be forged into work rolls. The load was applied by means of ceramic platens with

an average temperature, as given in Table 1. There was a

temperature gradient between upper and lower platen e.g.

for a nominal test temperature of 1000 C, the temperatures

of the platens were 990 and 1010 C, respectively. The temperature

of the test specimen was measured by means of a

thermocouple in the centre of the specimen. The specimen

was heated by induction for 2 min to the required test temperature

and then held at that temperature for 1 min before

the compression test was started. After reduction of the specimen

to 50% of the original height, the test specimen was

removed from the furnace and water quenched. The time between

the end of deformation and onset of water quench was

about 1 s.

Note: Axisymmetric hot compression tests (900–1100 C) on spray-formed AISI M3:2 high-speed steel were performed in order to establish

suitable parameters for hot forging of this material. Special attention was paid to establish the deformation conditions that lead to the

breakdown of the carbide network, present after spray forming, and to avoid fracture of the material as a result of deformation. By a

combination of microstructural analysis and finite element modelling, values for fracture stresses in this temperature range and critical strains

for the breakdown of the carbide network are given. The activation energy for hot deformation was also determined.

Influence of compression test parameters on microstructure: The initial microstructure of the as-sprayed material is

shown in Fig. 1 .As far as the carbide distribution is concerned three different length scales were present: I. Carbide network around 70 µm consisting of irregular

shaped carbides (highlighted by a black line in Fig. 1a), and close to elliptical or round carbides with average size of about 10 microns (marked by white lines in Fig. 1a); II. Close to elliptical or round carbides of micron size (examples marked by white circles in Fig. 1c); III. Rod shaped and rectangular carbides of sub micrometer size (Fig. 1c).

Carbides of category I and II were visible by optical microscopy

of polished samples (Fig. 1a). Carbides of group

III were only visible in SEM images (Fig. 1c). However, a

darkening in optical micrographs of the nital etched material

(Fig. 1b) is indicative of their presence. This can be seen by

comparing Fig. 1b and c. From these figures it is also evident

that the carbide density varies from cell to cell.

In order to investigate the influence of compression test

parameters on microstructure, these different length scales

have to be considered separately. The influence of strain on

the carbide network structure is shown in Fig. 2, which shows

a series of optical micrographs taken along the compression

axis of the test specimen. No deformation

of the cells is observed in Fig. 2a, taken from the area

in contact with the tool during compression. Moving towards

the centre of the specimen the carbide cell is first seen to be

deformed in Fig. 2b, and then only local remnants are observed

in Fig. 2c. There were no indications for the presence

of a carbide network in the centre of the specimen (Fig. 2d).

This behaviour was observed for all tests and indicates that

the carbide network is broken down by deformation amounting

to an equivalent plastic strain between 0.82 and 0.89,

depending on deformation temperature.

A higher

deformation temperature resulted in a slightly lower critical

strain. The deformation temperature influences the carbide

network in the direction perpendicular to the compression

axis. The cracking of large irregular-shaped carbides was observed

for deformation at 900 C (Fig. 3a) but not at 1100 C (Fig. 3b).

The number of carbides of category III strongly depends

on the deformation temperature, as is evident by comparing

Fig. 3a and b. In these figures, the small carbides are represented by the small white dots in the low-magnification

SEM images. The low magnification was chosen to provide

a better impression of the density distribution over a large

area, whereas the insets demonstrate the actual shape and size of the type III carbides. The high density of carbides at the

lower deformation temperature of 900 C in Fig. 3a is apparent. A low carbide density in conjunction with a strong local

density variation was observed for deformation at 1100 C (Fig. 3b).

The deformation temperature also influences the structure

of the matrix, as can be seen from Fig. 4. For deformation

below 1100 C (Fig. 4a and b), the matrix grain boundaries

were not revealed by nital etching. However, following deformation

at 1100 C, a well-developed matrix grain structure,

resembling a recrystallised structure, was observed (Fig. 4c).

However, recrystallisation did not seem to have taken place

homogenously, and was only observed in the bands of lower

carbide density (represented by absence of small black dots)

in Fig. 4c.

Links: No data

Reference: Not shown in this demo version.