Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Cr7C3 and Cr3C2 carbides in the chromium carbide coated on AISI D2 steel

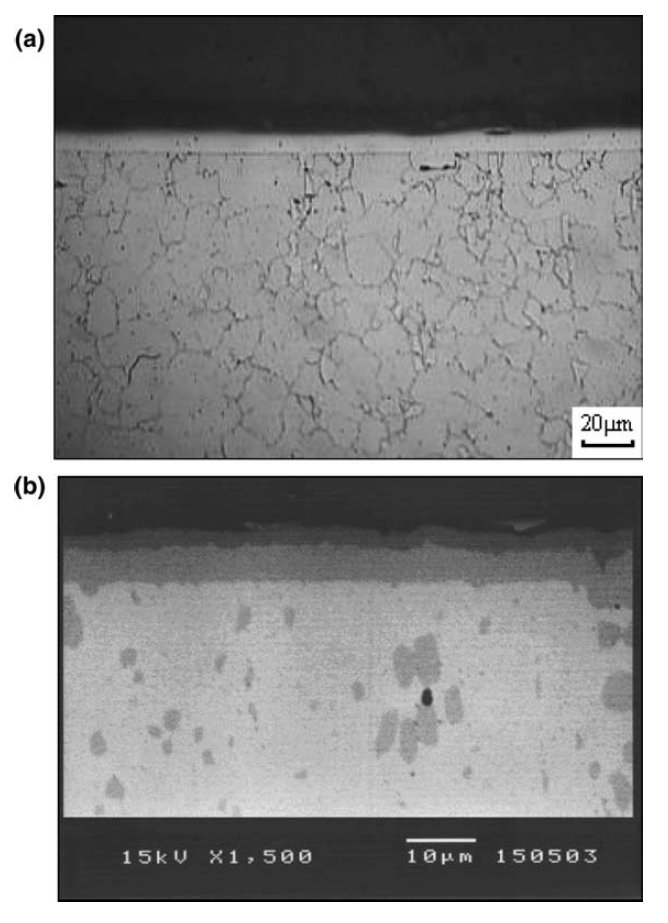

Figure 1: Optical and SEM-BEI micrograph of chromium carbide coated AISI D2 steel at 1000 C 3 h. Scale bars: 20, 10 µm.

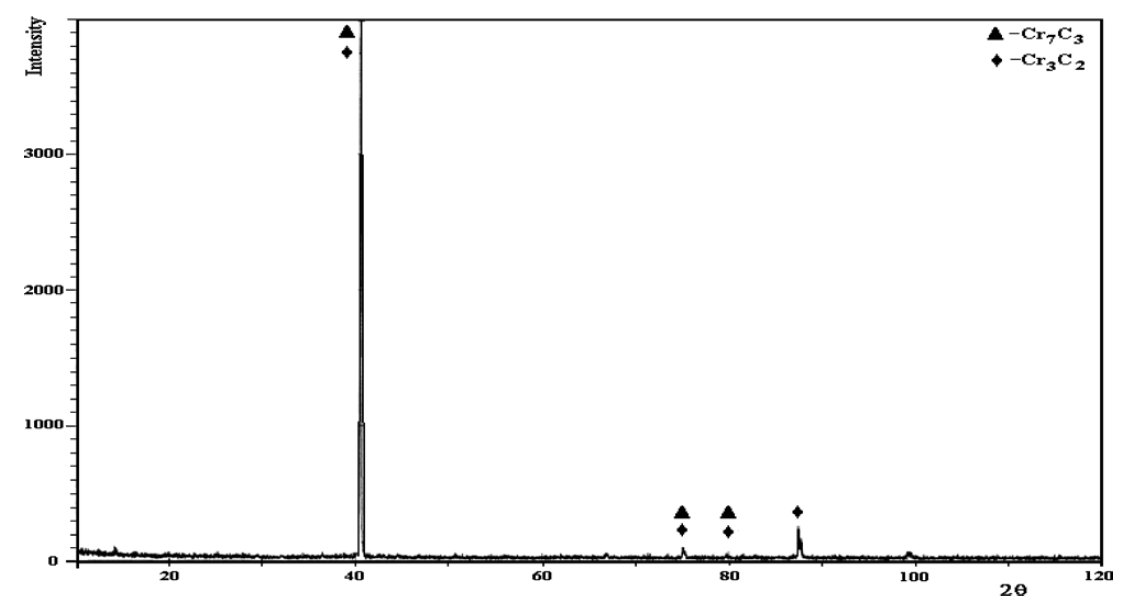

Figure 2: X-ray diffraction of chromium carbide coated AISI D2 steel at 1000 C 3 h.

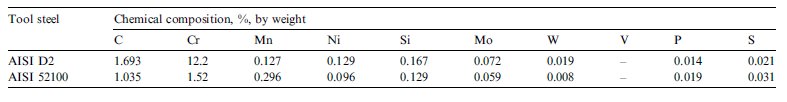

Table 1: Chemical compositions of AISI test materials.

Carbide name: Cr7C3, Cr3C2

Record No.: 737

Carbide formula: Cr7C3, Cr3C2

Carbide type: M7C3, M3C2

Carbide composition in weight %: No data

Image type: LM, SEM, XRD

Steel name: AISI D2

Mat.No. (Wr.Nr.) designation: 1.2379

DIN designation: X153CrMoV12

AISI/SAE/ASTM designation: D2

Other designation: No data

Steel group: Cold work tool steels

Steel composition in weight %: See the table 1.

Heat treatment/condition: In this study, AISI D2 steel was used as substrates,

the compositions of which are given in Table 1. The

samples to be coated were machined as coupons to

diameter of 20 and 5 mm in thickness, and prepared

metallographically by polishing with 1200 grid emery

paper at the final stage. Chromium carbide coating

was performed by pack method in the powder mixture

consisting of ferro-chromium, ammonium chloride and

alumina in an alumina crucible sealed with an alumina

led and alumina based cement. The process was performed

at 1000 C for 3 h in an electrical resistance furnace

followed by quenching in air.

Note: In this work, the tribological behavior of hardened, tufftrited and chromium carbide coated AISI 52100 steel balls against hardened

and chromium carbide coated AISI D2 steel discs have been studied under 1, 2 and 5 N loads. Chromium carbide coating was

performed by pack method. In this method, AISI 52100 steel sample was coated in the powder mixture consisting of ferro-chromium,

ammonium chloride and alumina. Tufftriting treatment was performed in the commercial salt bath. The wear test was carried

out with ball-on-disc configuration system. Test conditions covered 0.125 m/s speed and 1, 2 and 5 N loads.

The chromium carbide coating of AISI D2 steel performed

by pack method in the powder mixture consisting

of ferro-chromium, ammonium chloride and

alumina at 1000 C for 3 h. Optical micrograph and

scanning electron microscopy-back scattered electron

image (SEM-BEI) cross-sectional view show that chromium

carbide layer formed on AISI D2 steel surfaces

are of compact, smooth and porosity-free morphology

and homogeneous the entire surface of steel sample.

Fig. 1(a) and (b) show the optical microstructure and

SEM-BEI micrograph of chromium carbide coated AISI

D2 steel, respectively. In this figures, two regions are observed.

These are: (a) chromium carbide layer which includes

Cr7C3 and Cr3C2 phases confirmed by X-ray

diffraction analysis as shown in Fig. 2, and (ii) steel matrix.

Chromium carbide coating layer thickness was

measured as 13 µm by an optical micrometer attached

to the optical microscope. The hardness of chromium

carbide layer was measured as 1850 HV(0.025). It was found to be much higher than that of the hardened AISI

D2 steel (61 HRc). The main advantages of chromium

carbide coated steels are that the former has a diffusion

controlled chromium carbide layer, which has the higher

adhesion than the mechanical bonded coatings.

Links: No data

Reference: Not shown in this demo version.