Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Carbides in Vanadis PM steel

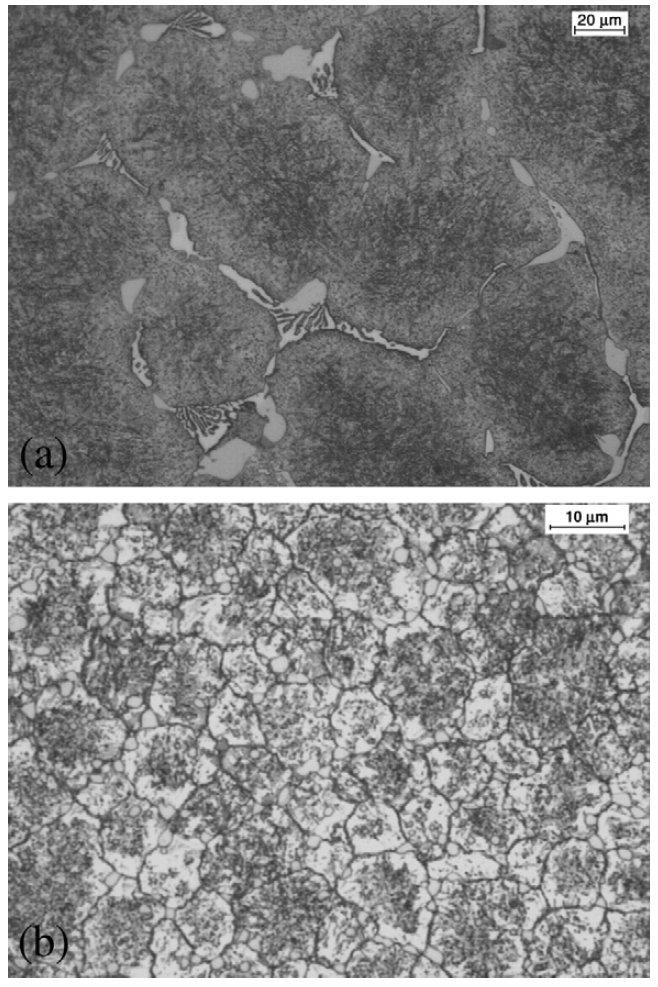

Figure 1: Optical micrographs of V4 steel: (a) as-cast,(b) as-sprayed, Scale bars: 20, 10 µm.

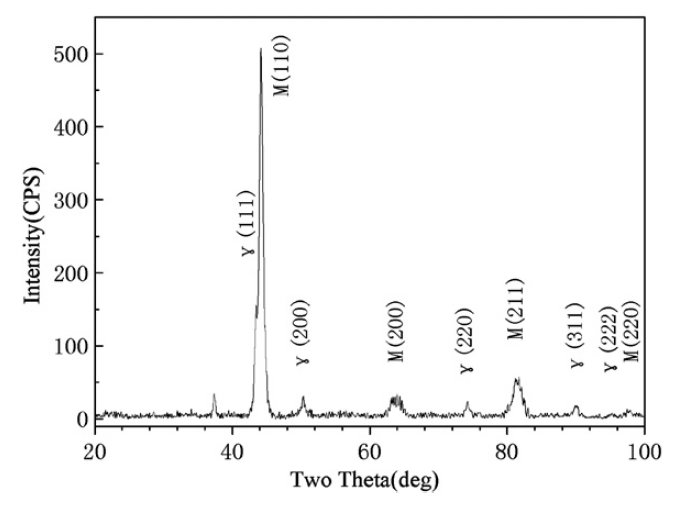

Figure 2: X-ray diffraction spectrum of the as-sprayed V4 steel.

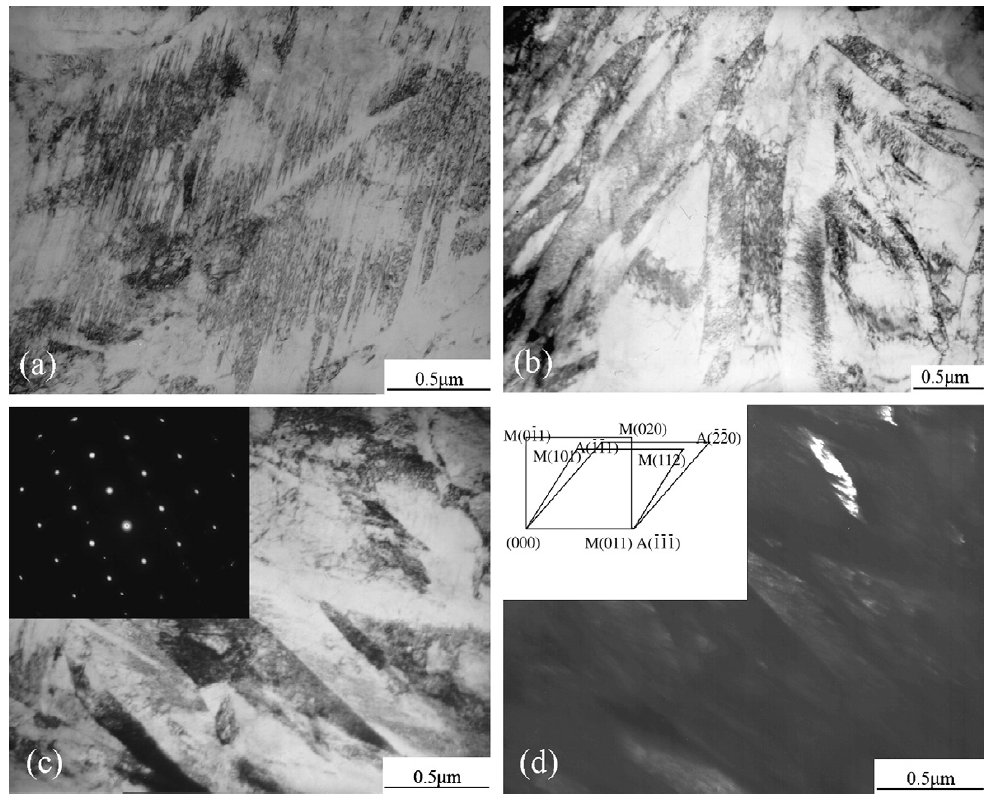

Figure 3: TEM micrographs: (a) twined martensite, (b) lath martensite, (c) retained austenite (bright field) and its diffraction

patterns, (d) retained austenite (dark field) and standardization of diffraction patterns. Scale bars: 0.5 µm.

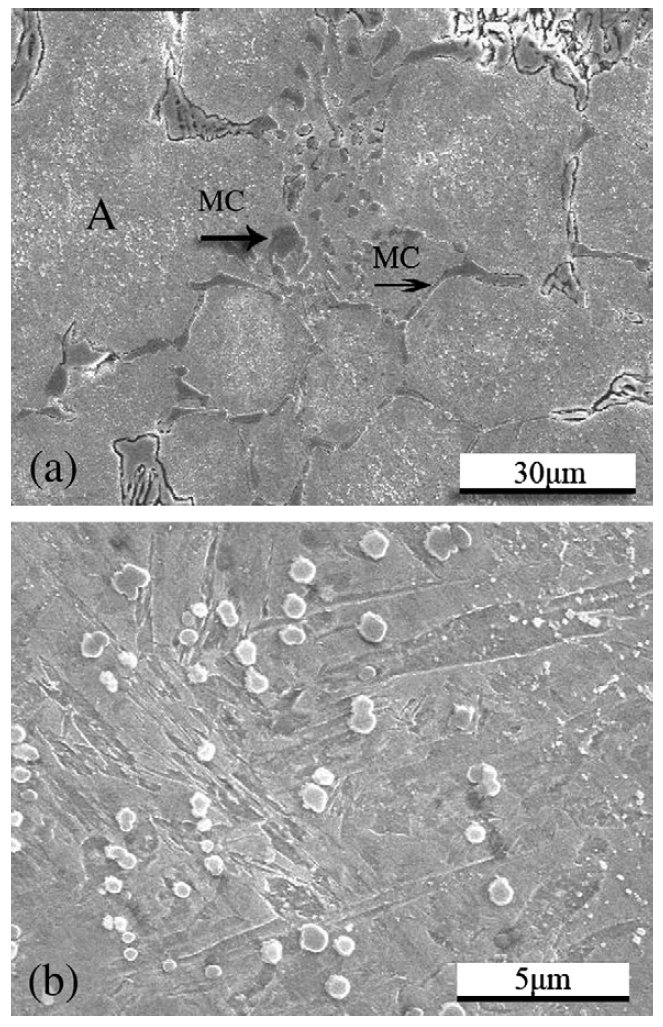

Figure 4: SEM micrographs of the as-cast V4 steel. Scale bars: 30, 5 µm.

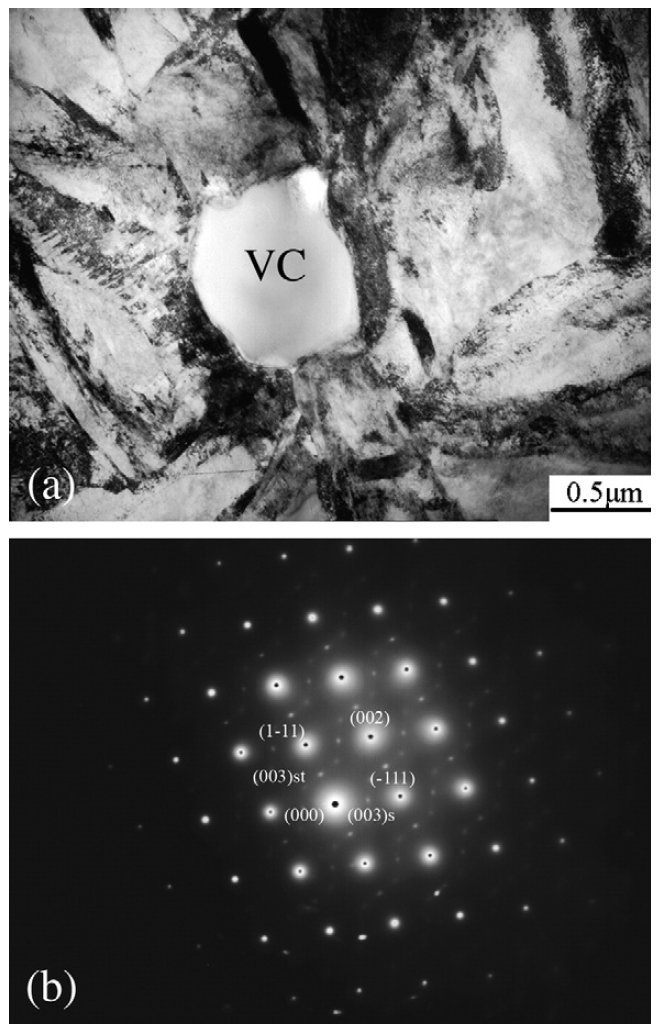

Figure 5: (a) TEM micrograph of VC in the as-sprayed V4 steel, (b) selected area diffraction patterns in [011] zone axis of VC. Scale bar: 0.5 µm.

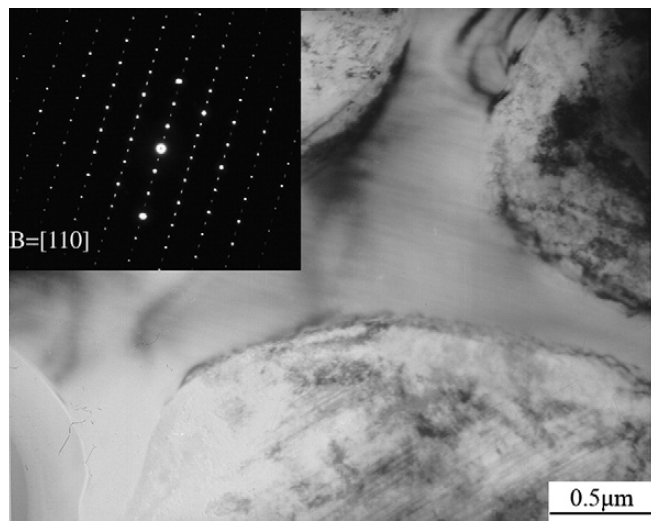

Figure 6: TEM micrograph of the M7C3 carbide in the as-sprayed V4 steel and its selected area diffraction patterns. Scale bar: 0.5 µm.

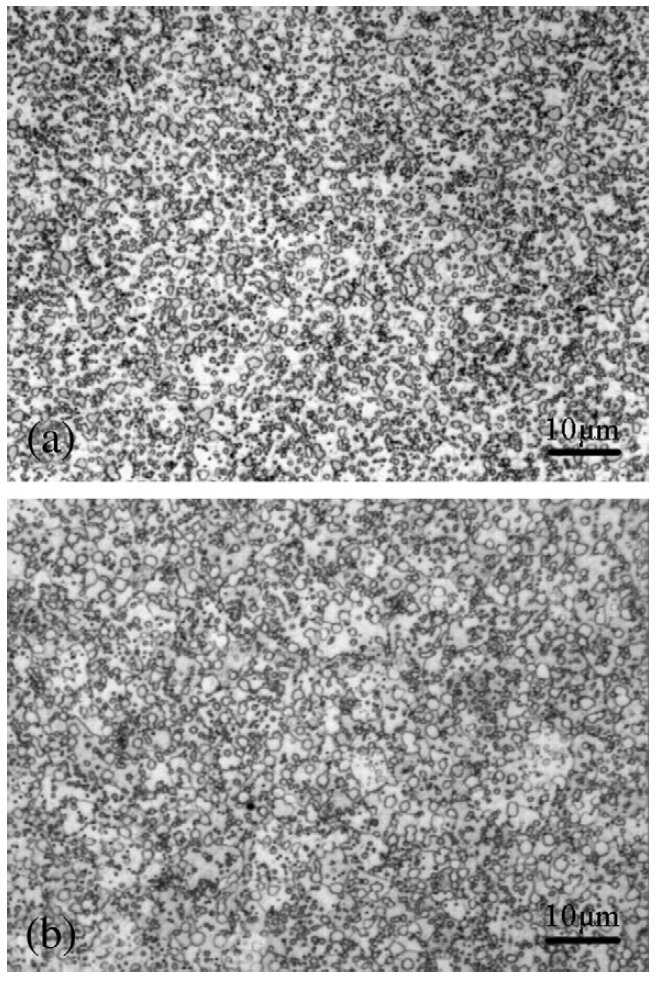

Figure 7: Comparison of V4 annealed microstructures: (a) spray forming, (b) powder metallurgy. Scale bars: 10 µm.

Carbide name: VC, M7C3

Record No.: 738

Carbide formula: VC, M7C3

Carbide type: MC, M7C3

Carbide composition in weight %: No data

Image type: LM, SEM, TEM

Steel name: Vanadis 4

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: No data

Other designation: No data

Steel group: PM high alloyed steels

Steel composition in weight %: 1.5% C, 1.0% Si, 0.4% Mn, 8.0% Cr, 1.5% Mo, 4.0% V.

Heat treatment/condition: The steels were melted in a vacuum induction furnace and

then cast into rods as feedstock for spray forming. The

feedstock was heated in an induction furnace and soaked at

above melting point for 20 min. The molten metal flow rate

was set at approximately 0.1 kg/s, using N2 with a pressure of

2.2 MPa as atomizing gas. The atomized droplets were cooled

and driven towards a revolving substrate to form a condensed

product. The distance from the nozzle to the substrate was set

as 360 mm, and the copper substrate rotated at a speed of

10 rpm during atomization and deposition. The whole spray

forming process was completed in about 40 s, and a gaussshaped

billet with about 130 mm in diameter and 30 mm in

height was obtained.

The as-sprayed billet was machined into specimens with a

thickness of 16 mm. The specimens were then heated at a rate

of 10°C/min to the rolling temperatures of 850°C, 900°C,

950°C, 1050°C, 1150°C, respectively. After holding for 15 min,

the specimens were rolled in a single 60% reduction pass, and

then cooled to room temperature in the sand. Three groups of

as-rolled specimens were annealed at 850°C, 900°C, 950°C

respectively, with each group containing five specimens rolled

at different temperatures. After being isothermal held for 2 h,

the specimens were cooled to 500°C at a rate of 30°C/h, and

then cooled in air. The most ideal microstructure, which was

obtained by the as-sprayed steel rolled at 1050°C and

annealed at 900°C, was chosen from the annealed specimens

and compared with that of the commercial V4 steel made by

powder metallurgy (By UDDEHOLM, Sweden).

Note: The as-sprayed microstructure of the Vanadis 4 steel was studied. It was observed that the

as-sprayed microstructure consists of martensite, retained austenite and uniformly

distributed spheroidal carbides. The Kurdiumov–Sachs crystallographic relation between

martensite and retained austenite is confirmed by transmission electron microscope. No

macro segregation or network carbides are found. This can be explained in terms of the

rapid solidification of spray forming for microstructure refining. The steel obtained by the

new processing has a uniform carbide distribution, and the average carbide size is even

smaller than the equivalent in the powder metallurgical Vanadis 4 steel. It was proved that

spray forming can be considered as a new and high-efficient way to replace powder

metallurgy for the production of Vanadis 4 steel.

As shown in Fig. 1a, the microstructure of the as-cast V4 steel

contains coarse eutectic carbides rich in Mo, Cr and V, which

segregate at the prior austenite grain boundaries during

solidification. These carbide arrangements will lead to very

low toughness and ductility of the materials. Fig. 1b shows

the microstructure of the as-sprayed material consisting of

fine, homogeneous and fully spheroidal grains ranging from

8 to 10 µm, which was substantially finer than the conventionally

cast equivalent. No carbide networks or large irregular

carbides were found, and the fine spheroidal carbides were

uniformly distributed throughout the microstructure. The

carbides located at the grain boundary were relatively larger

compared with those inside the grains.

The X-ray diffraction analysis revealed the presence of

martensite, and a considerable quantity of metastable

retained austenite in the matrix (Fig. 2). The cause of the

retained austenite, as reported for spray formed D2 and

rapid solidification D2 steel, is that much of the alloying elements were dissolved in the austenite during the spray forming and the rapid solidification stabilized the austenite

and therefore decreased the martensite start temperature Ms.

The TEM observation showed that the microstructure was

predominantly twined martensite. Some acicular martensite

and lath martensite were occasionally found. The representative

morphology of the martensite was shown in Fig. 3a

and b. It could be seen from Fig. 3c and d that the retained

austenite was arranged in form of layers between martensite strips. The selected area diffraction pattern showed the

Kurdiumov.Sachs orientation relation of (011)alpha'//(111)gamma between

the austenite and the martensite.

Carbides are important phases providing the steel with high

hardness and high wear resistance. The TEM analysis of the

cold work steel showed two types of carbides in the matrix:

vanadium riched MC (VC) and chromium riched M7C3 ((Cr,

Fe)7C3). It is interesting to compare the morphology of the

carbides in the as-sprayed microstructure with that in the ascast

one. As shown in Fig. 4a, many strip or short rod coarse

eutectic VC carbides (shown by arrows) are located along the

grain boundaries. But in the as-sprayed microstructure, fine

spheroidal VC carbides are uniformly distributed on the grain

boundaries, no coarse VC carbides could be found. The

morphology of VC is shown in Fig. 5a. This difference could

be explained by comparing the characteristics of VC formation

during solidification process. The vanadium is a strong

carbide-forming element, and the vanadium carbides

obtained by conventional cast could be divided into primary

carbides and eutectic carbides. The primary vanadium carbides

precipitate first from the molten steel during the

solidification process, and they grow without restriction

in various directions. Thus the primary carbides have a trend of forming large conglomerations. Other eutectic carbides are

in shape of strip or shot rod. This is because the VC is a typical

faceted crystal, but the austenite is non-faceted crystal,

therefore they tend to form divorced eutectic and the VC

carbides grow along the austenite grain boundaries during

solidification.

The uniform distribution of the spheroidal MC carbides in

the as-sprayed materials indicated that the eutectic reaction

was greatly restrained as the result of the rapid solidification.

The microstructural characteristics of the as-sprayed materials

critically depend upon the solidification history of the

droplets. During the spray forming process,

the melt stream is broken into finer droplets in diameters

ranging from 5 to 200 µm. The small droplets might have

solidified completely, the medium sized partially solidified

and the larger still in their liquidity when they arrived on the

deposition surface. The droplets will ideally form a mushy

zone consisted of liquid and solidified metal and the thickness

is only a few millimetres on the surface of the billet. The

mushy zone is expected to exist during the whole spray

forming process. When the droplets with high velocities hit

the surface of the mushy zone, dendrites form during flight

experience and semi solidified droplets may break up and

remelt. Those dendritic fragments having not been remelt will

be the new nuclei for the rapid solidification which is

promoted by the comparably cold atomizing gas. The formation

of spheroidal grains is proposed to evolve from the homogenization of dendrites without being deformed extensively,

or from the growth and coalescence of the deformed or

fractured dendrites.

The atomized droplets undergo a rapid solidification by the

effective convection of surrounding gas, and therefore, solute

segregation can be greatly depressed. In addition, the impact

of the droplets causing turbulences in the mushy zone leads to

further homogeneous thermal balance and chemical composition.

The amount of the residual liquid that could be at the

eutectic chemical composition is reduced due to the nonequilibrium

solidification process. Therefore the formation of

the elongated vanadium carbide is greatly suppressed and

results in fine spheroidal carbides.

The typical morphology of the VC carbide and its diffraction

patterns with zone axis of [011] are shown in Fig. 5. It is of

interest to note that the superlattice spots existed in the

diffraction pattern, which revealed the ultrafine structure of

the VC. The VC is in face-centered cubic (FCC) crystal

structure, and the atom diameter ratio of the carbon and the

vanadium is rC/rM=0.57(<0.59). The smaller the ratio the

higher the trend to form simple close-packed structure. The V

atoms are packed as face-centered cubic and the C atoms filled

in the octahedron interstice. But some C atoms may be absent

in the octahedron interstice of the crystal, which makes the

atomic ratio of C to V in the lattice less than 1. For example, the

chemical formula of vanadium carbide may vary form VC0.5 to VC.

Some eutectic M7C3 carbides existed along the grain

boundaries in the as-cast materials, and others precipitated

from the matrix and their morphology are shown in Fig. 4b,

which is region A in Fig. 4a. They were spherical and uniformly

distributed since they precipitated from the matrix. Most of

the M7C3 carbides in the as-sprayed microstructure are

spheroidal with diameter of about 180 nm, and most of them

are distributed inside the grains. Few dog-bone-like M7C3

carbides, as shown in Fig. 6, are observed. However, they are

only about 3–4 ìm long and are far smaller than those in the

as-cast microstructure.

After spray forming, the billets were hot rolled and then

annealed at different conditions in order to optimize the processing

parameters. The best microstructure obtained, Fig. 7a,

consists of fine carbides dispersed homogeneously in the

ferrite matrix. It was obtained by the as-sprayed steel rolled at

1050°C and then annealed at 900°C. The average carbide size

is even smaller than the equivalent in the powder metallurgical

V4 steel (Fig. 7b). The crucial reason for obtaining the

excellent microstructure is attributed to the spray forming

used for microstructure refinement. It is important to note

that, unlike conventional cast high alloy steels, the as-sprayed

steels showed good workability at temperatures ranging from

850 to 1150°C as no crack have been found in the specimens,

which have experienced severe deformation. The enhanced

workability of the as-sprayed steel is also attributed to the

refined microstructure with small equiaxed grains and evenly

distributed fine spheroidal carbides. The large deformation is usually used on conventional cast high alloy steels in order to

break up the coarse carbides, and the steels are sensitive to

crack during hot working because of the coarse grains and

coarse carbide networks.

Links: No data

Reference: Not shown in this demo version.