Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

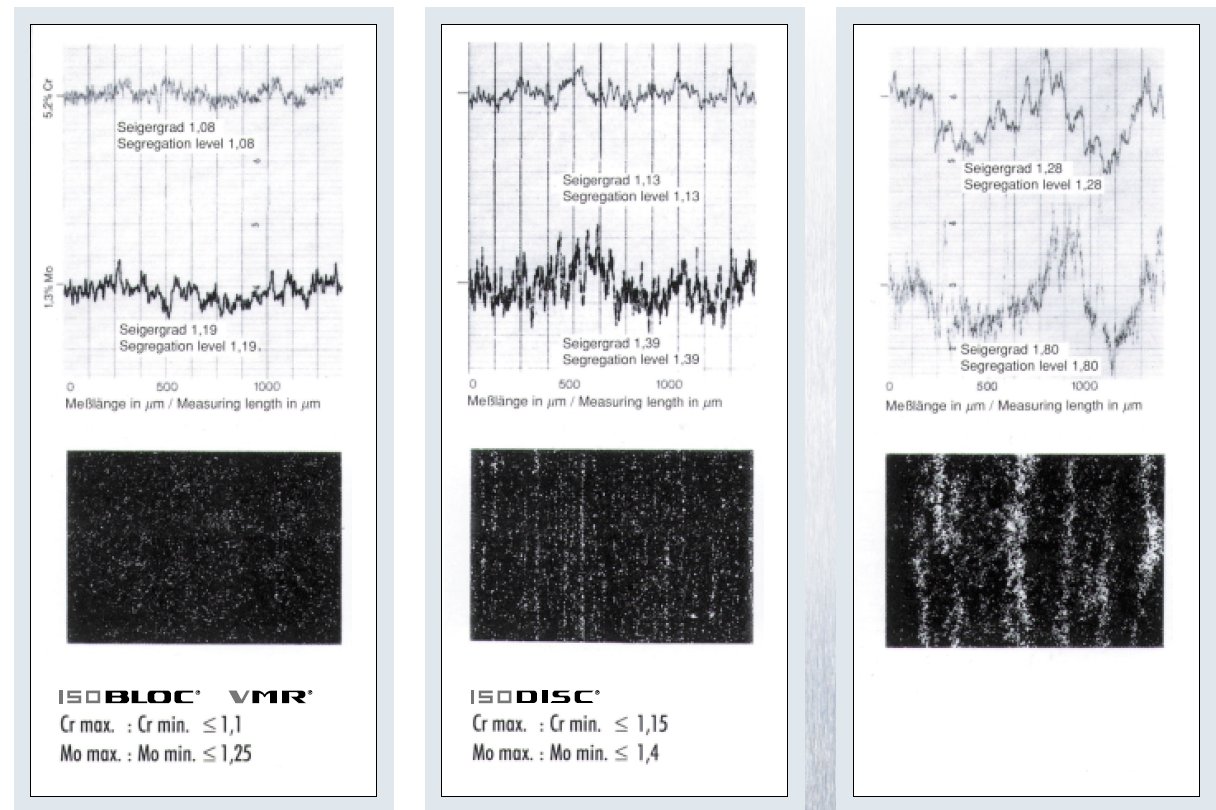

Cr and Mo concentration profiles in 1.2344 steel

Figure 1: Cr and Mo concentration profiles.

Carbide name: No data

Record No.: 741

Carbide formula: No data

Carbide type: No data

Carbide composition in weight %: No data

Image type: EPMA

Steel name: 1.2344

Mat.No. (Wr.Nr.) designation: No data

DIN designation: X40CrMoV51

AISI/SAE/ASTM designation: AISI H13

Other designation: No data

Steel group: Hot work tool steels

Steel composition in weight %: 0.35-0.42% C, 0.80-1.20% Si, 0.25-0.50% Mn, max. 0.03% P, max. 0.02% S, 4.80-5.50% Cr, 1.20-1.50% Mo, 0.85-1.15% V.

Heat treatment/condition: As-hardened condition.

Note: During solidification of an ingot, the steel production process involves unavoidable alloying element segregations. On a grain size

scale this is known as microsegregations or crystal segregations, on the ingot scale they are called macrosegregations or ingot segregations. These

inhomogeneities exert a negative effect on the transverse toughness properties, above all.

The positive effects of the production technology employed for 1.2344 steel on microsegregation are shown most effectively using

the electron beam microprobe method to measure the difference in concentration of alloying elements.

Links: No data

Reference: Not shown in this demo version.