Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Carbides in tool steels with high chromium content

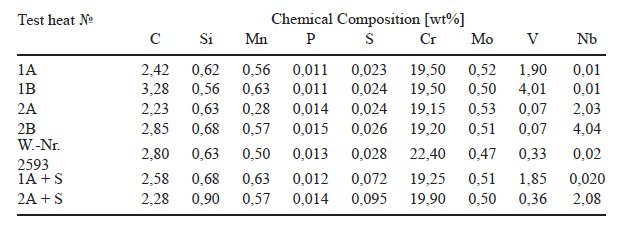

Table 1: Chemical composition of chromium alloyed castings with additions of vanadium

or niobium.

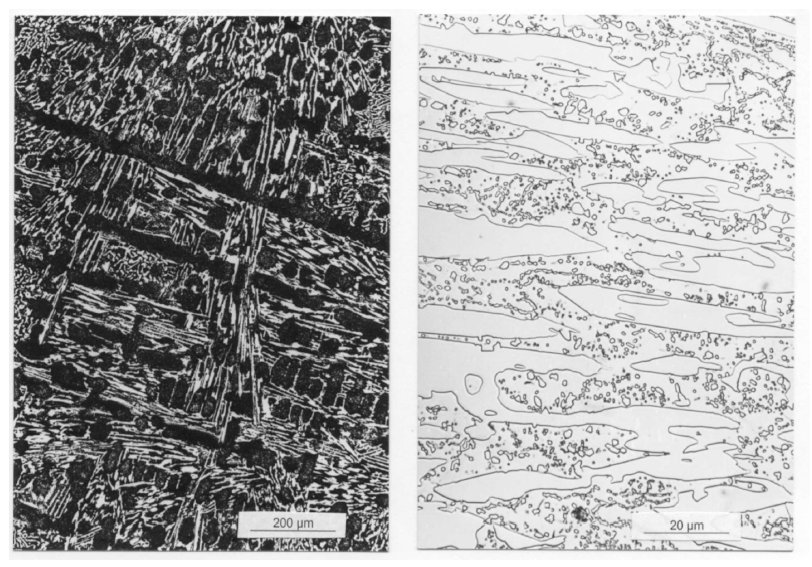

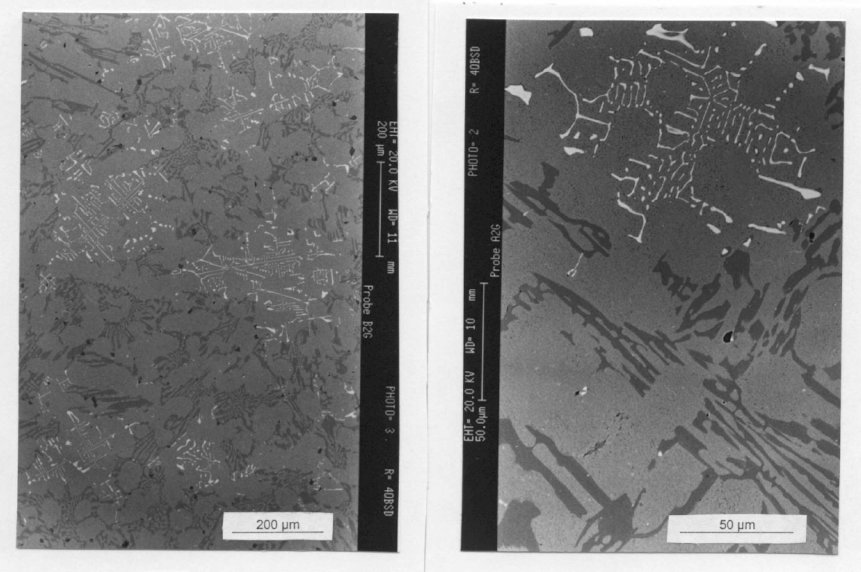

Figure 1: Microstructure of the cast alloy W.-Nr. 1.2593 (2.8% C; 25% Cr). Scale bar: 200, 20 µm.

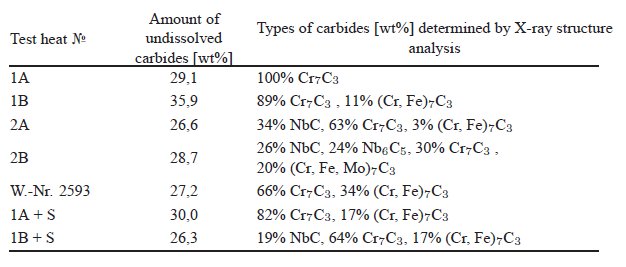

Table 2: Carbides in the tested cast alloys in the annealed condition.

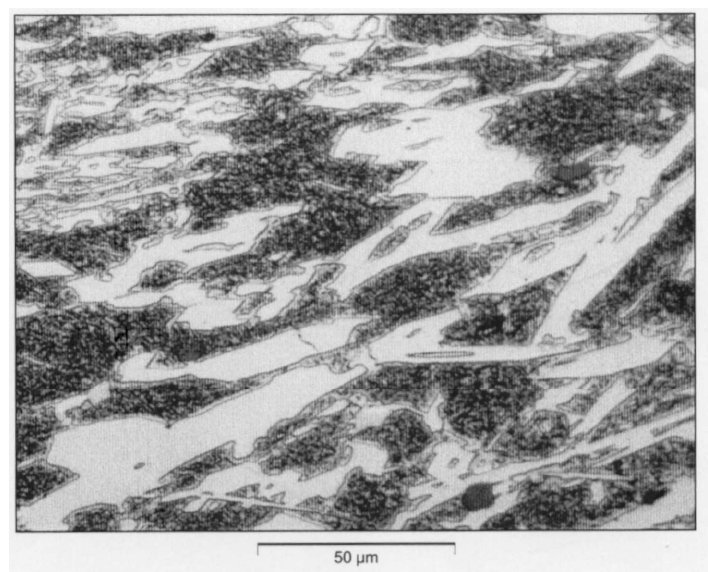

Figure 2: Microstructure of the cast alloy 1B (3.3% C; 19.5% Cr; 2.0% V). Scale bar: 50 µm.

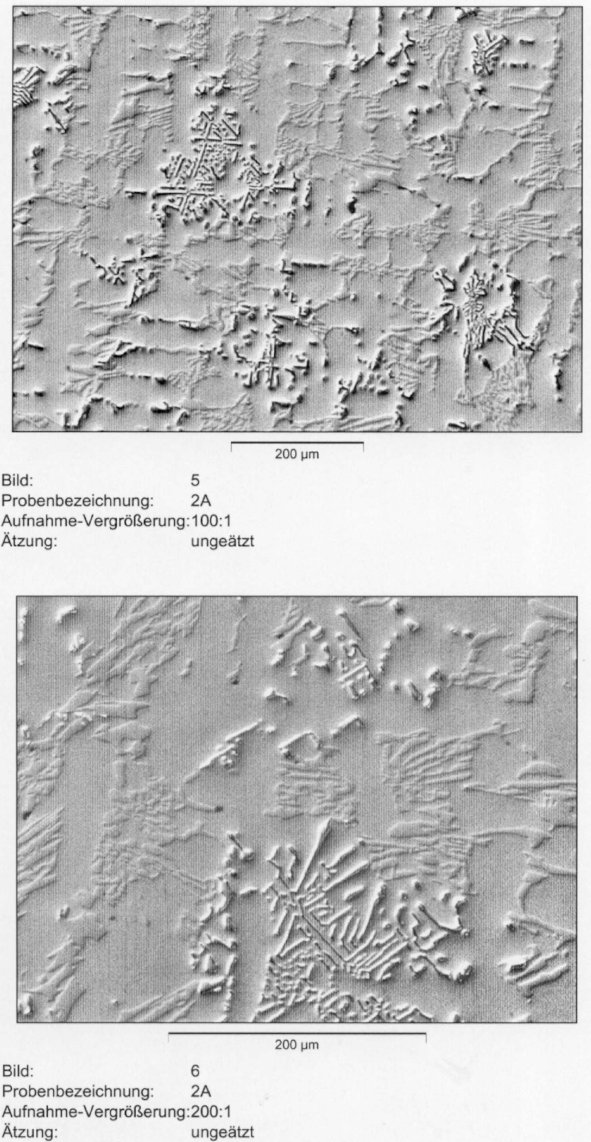

Figure 3: Microstructure of the cast alloy 2A (2.3% C; 19.2% Cr; 2.0% Nb). Bright

carbides NbC, dark carbides Cr7C3 (SEM photo). Scale bars: 200, 50 µm.

Figure 4: Microstructure of the cast alloy 2A (2.3 % C; 19.2 % Cr; 2.0 % Nb). Etched 5

% Nital and relief polished with alumina. Scale bar: 200 µm.

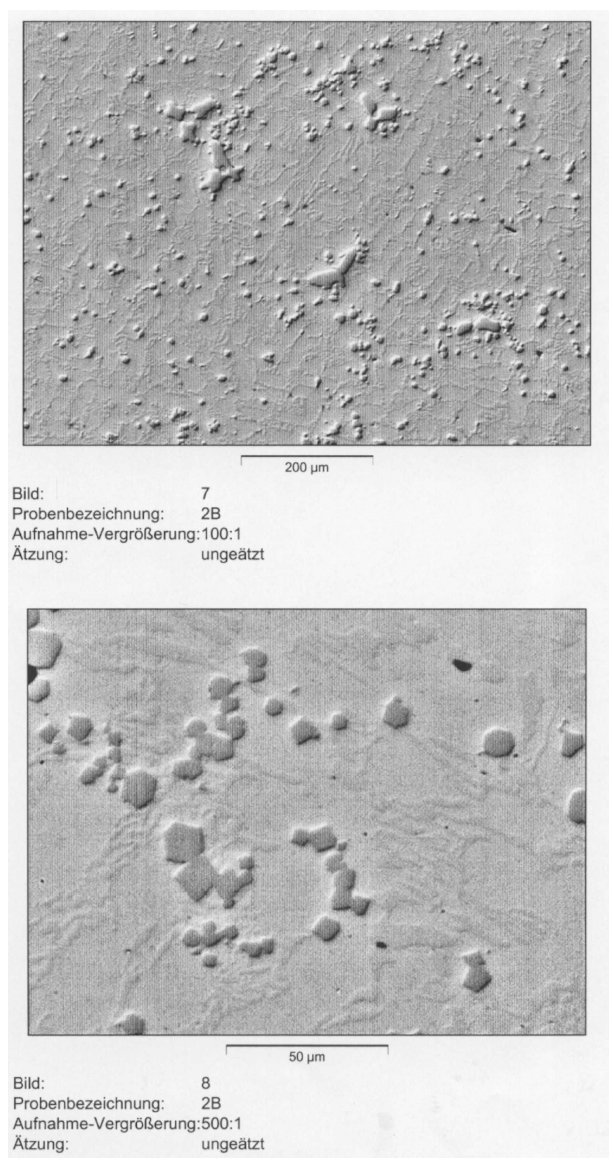

Figure 5: Microstructure of the cast alloy 2B (2.9% C; 19.2% Cr; 4.0% Nb). Etched 5%

Nital and relief polished with alumina. Scale bars: 200, 50 µm.

Carbide name: See the table 2.

Record No.: 744

Carbide formula: See the table 2.

Carbide type: See the table 2.

Carbide composition in weight %: No data

Image type: LM, SEM, XRD

Steel name: See the table 1.

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: No data

Other designation: No data

Steel group: Tool steels

Steel composition in weight %: See the table 1.

Heat treatment/condition: See the text bellow.

Note: There is a common wish to increase the wear resistance of cold work steel.

The possibility to improve wear resistance by the addition of more alloying

elements is limited, due to the loss of toughness. Therefore one tries to extend

the weight percentage of alloying elements like niobium and vanadium which

form very hard carbides.

The solubility of alloy carbides at austenitizing temperature and their

precipitation at higher tempering temperatures causes secondary hardness.

Contrary to vanadium carbides, niobium carbides have a very poor solubility

at hardening temperature.

Table 1 shows the analysis of these test melts with about

20% Chrome and additions of 2 and 4 wt% vanadium or niobium. The test

melts had a weight of 5 kg and were poured in ceramic moulds of 60mm

square. To reduce the cooling rate of the melts, the moulds were preheated

at 1000 C and embedded in sand.

Figure 1 shows the microstructure of a V- and Nb-free cast alloy W.-Nr.

2593 taken from an extrusion cylinder. All carbides in the microstructure of

Fig. 2 are of the type Cr7C3 as has been proven by X-ray structure analysis

(see Table 2).

By the addition of 2 or 4% vanadium, the carbide type in themicrostructure

remains unchanged Cr7C3 (Fig. 2). Vanadium carbides of the typeMC have

not been detected (see Table 2). It is to assume that the added vanadium is

completely dissolved in chromium carbide.

On the other hand the addition of niobium changes the microstructure

completely. After alloying niobium the structure shows two types of carbides,

the chromium rich carbide Cr7C3 and the niobium carbide NbC (see Table 2). In the alloy with about 2% Nb (alloy 2A) the niobium carbide has

an entectic appearance, but a crystallographic solidification of these niobium

carbides can be recognized in Fig. 3. These NbC must have been formed

between the begin of solidification and the eutectic temperature where the

residual melt decomposes to chromium carbide and austenite. Figure 4

shows the same microstructure etched and relief polished. One can clearly distinguish the two carbide types. The hard NbC is distinctly elevated while the softer Cr7C3 is more blurred in the background. In the melt with 4% niobium, the niobium carbide has another shape. At

this content niobium carbide directly precipitates at higher temperatures in the melt before the ferritic solidification of the alloy starts. By this way the NbC could here develop en exact crystallographic cubic or octaeder form as Fig. 5 shows. The cubic niobium carbides are random distributed in the structure. Some carbides have grown up to about 50 µm,(Fig. 5).

Links: No data

Reference: Not shown in this demo version.