Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Cr7C3 and NbC carbides in 2.50C-3.30Si-6.20Cr-1.42Ni-2.20Mo-2.60V-0.98W steel

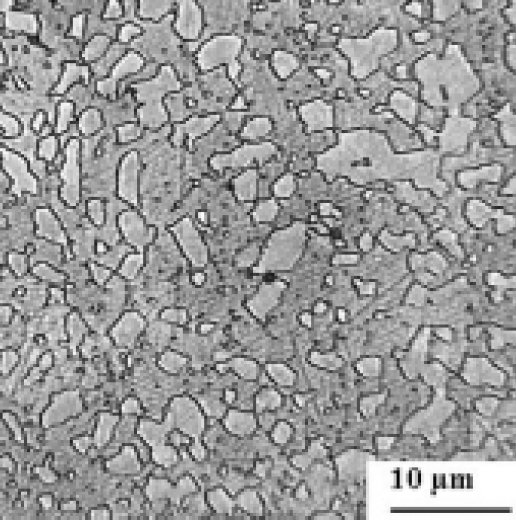

Figure 1: Microstructure of the steel after soft annealing, scale bar: 10 µm.

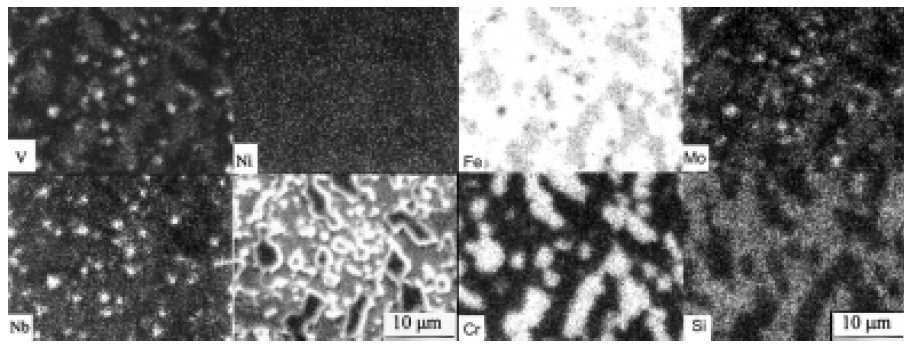

Figure 2: Distribution of alloying elements in the investigated steel (X-ray maps).

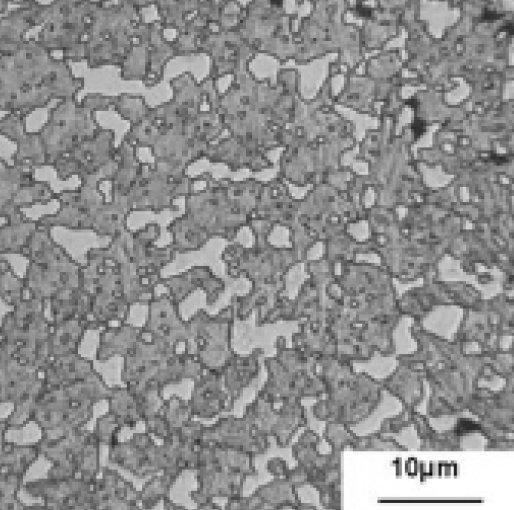

Figure 3: Microstructure of the hardened steel (austenitizing temperature

of 1050°C), scale bar: 10 µm.

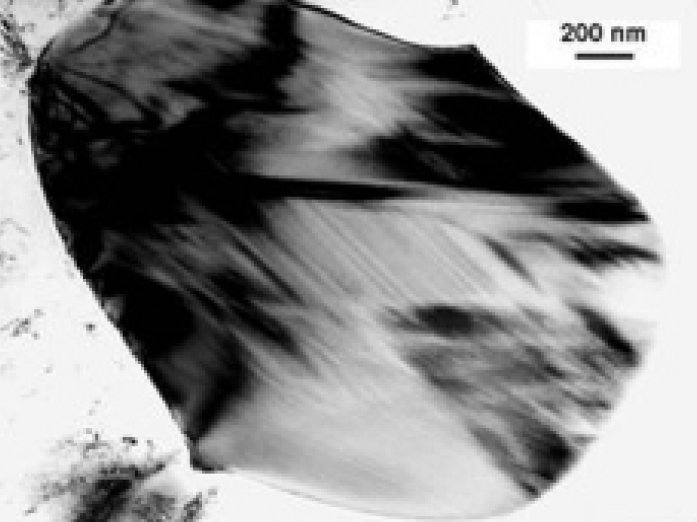

Figure 4: Primary Cr7C3 carbide particle in the hardened steel

(TEM-bright field), scale bar: 200 nm.

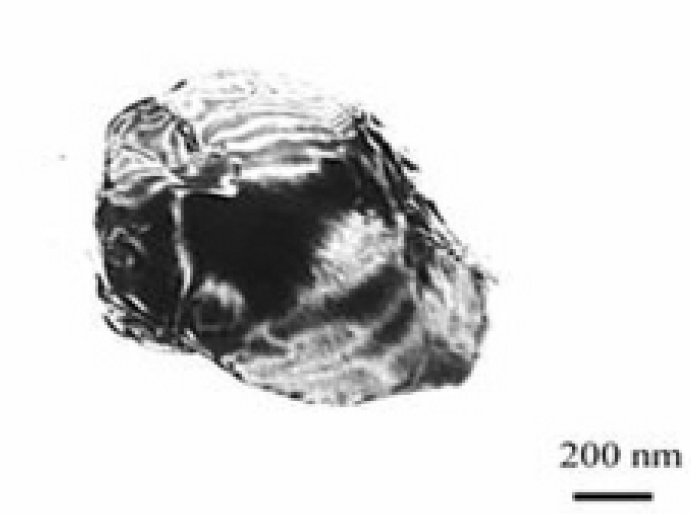

Figure 5: Primary NbC carbide particle in the hardened steel

(TEM-dark field), scale bar: 200 nm.

Carbide name: Cr7C3, NbC

Record No.: 745

Carbide formula: Cr7C3, NbC

Carbide type: M7C3, NbC

Carbide composition in weight %: No data

Image type: SEM, TEM, X-ray

Steel name: 2.50C-3.30Si-6.20Cr-1.42Ni-2.20Mo-2.60V-0.98W steel

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: No data

Other designation: No data

Steel group: PM tool steels

Steel composition in weight %: 2.50% C, 3.30% Si, 6.20% Cr, 1.42% Ni, 2.20% Mo, 2.60% V, 2.60% Nb, 0.98% W, 0.03% N, 0.04% O, 0.03% P, 0.02% S.

Heat treatment/condition: The investigated tool steel was prepared using a

powder-metallurgy process. The powder was produced

by atomizing the melt using a nitrogen flow at a pressure

of 400–600 kPa.

Chromium, vanadium, molybdenum and niobium are

the main carbide-forming elements present in steel. The

contents of oxygen and nitrogen, which are of the order

of hundreds of ppm, are in accordance with the method

used for the powder preparation.

The powder was compacted using a hot isostatic

pressing (HIP) method. The steel capsule (length 200

mm and diameter 40 mm) containing the powder was

evacuated. The HIP processing was performed at 1120°C under an argon pressure of 147 MPa for 4 h. The

residual porosity of the hot isostatically pressed product

was negligible.

The heat treatment of the compacted semi-product

consisted of soft annealing, austenitizing, hardening and

tempering. The soft annealing was performed at 780 °C

for 8 h with subsequent slow cooling to 680 °C, and then

holding at this temperature for 2 h. Next, the steel was

slowly furnace cooled to room temperature. The

conditions of soft annealing were selected with the aim

of obtaining a desirable growth of carbide particles.

After this treatment, the hot isostatically pressed

semi-product was cut into samples of size approximately

5 mm × 10 mm × 10 mm. To characterize the influence

of the heat treatment on its properties, the steel was

austenitized for 30 min at temperatures ranging from

1000 °C to 1150 °C, after which it was cooled in nitrogen

with a pressure of 500 kPa to 600 kPa in a vacuum

furnace. As a final step, the hardened steel was tempered

three times at various temperatures in the range 150–700

°C with intermediate air-cooling.

Note: The microstructure of a P/M tool steel with 2.5% C, 3.3% Si, 6.2%Cr, 2.2%Mo, 2.6%V, 2.6%Nb and 1.0%W was investigated

for various heat-treatment conditions, with the aim of achieving an alloy with the maximum hardness. The heat treatment of the

compacted semi-product consisted of soft annealing, austenitizing, hardening and tempering.

The microstructure of the investigated alloy is shown

in Figure 1. It consists of carbide particles that are and

uniformly distributed in the matrix and surrounded with

the matrix. The carbide particles are of two different

sizes.

EDAX microanalysis was used for to determine

theation of chemical composition of the carbides. The

X-ray maps in Figure 2 show that chromium is the main

constituent of the coarse carbides. The size of these

particles ranges from approximately 5 µm to 10 µm.

Vanadium, niobium and molybdenum are present mainly

in the smaller carbide particles of with diameters less

than 3 µm. Vanadium and niobium preferably tend to

form MC carbides. The number of smaller V-, Nb- and

Mo-rich particles is much higher than that of the coarse

Cr-rich particles.

The microstructure of the hardened samples consists

of particles uniformly distributed in the matrix of the

solid solution, as can be seen in Figure 3.

The microstructure of the hardened steel is similar to

that of the soft annealed steel with two types of particles.

The coarse particles of irregular shape, see Figure 4,

were identified using TEM as Cr7C3, and the smaller

particles (Figure 5) as NbC.

The volume fraction of the primary carbide particles

in the steel depends on the austenitizing temperature, and

the volume fraction of the carbides decreases with the

increasing temperature of austenitizing, due to their

dissolution in the austenite. The finest carbides were

present in the steel hardened at 1050 °C.

The final properties of many highly alloyed tool

steels are adjusted by tempering at relatively high

temperatures (500–600 °C), where the peak of the

secondary hardness occurs. To find the optimum tempering conditions for our material, the hardened

samples were tempered (tempering time: 3 × 1 h) at

temperatures from 150 °C to 700 °C and detailed

investigations of the microstructure, the phase composition

and the mechanical properties after tempering

were performed.

Links: No data

Reference: Not shown in this demo version.