Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Fe3C, VC, M7C3 and M23C6 carbides in heat resistant 12Kh1MF steel

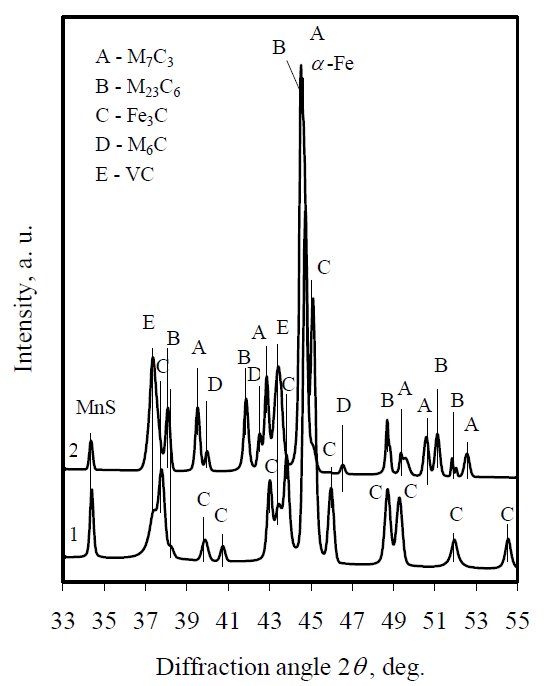

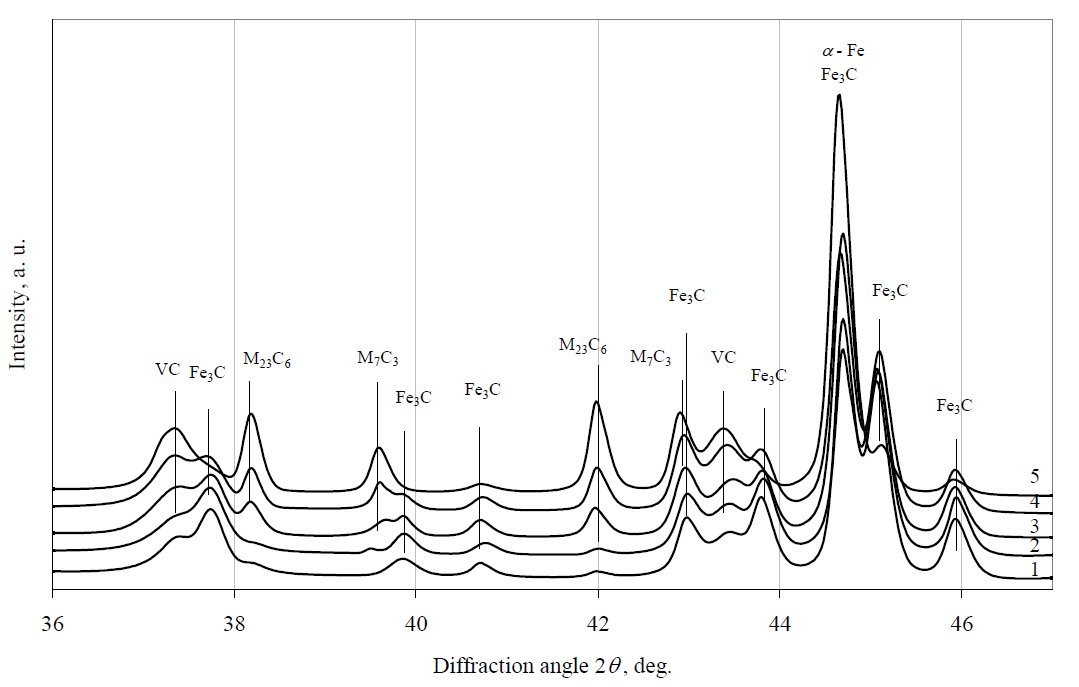

Figure 1: X-ray diffraction patterns of 12Kh1MF virgin (curve 1)

steel and exploited 227000 h at 550 °C temperature and

pressure of 14 MPa (curve 2).

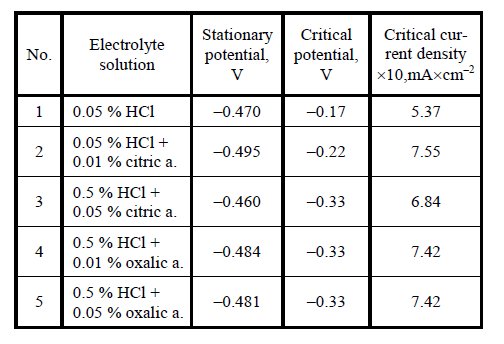

Table 1: Electrochemical parameters of 12Kh1MF steel in electrolytes solutions.

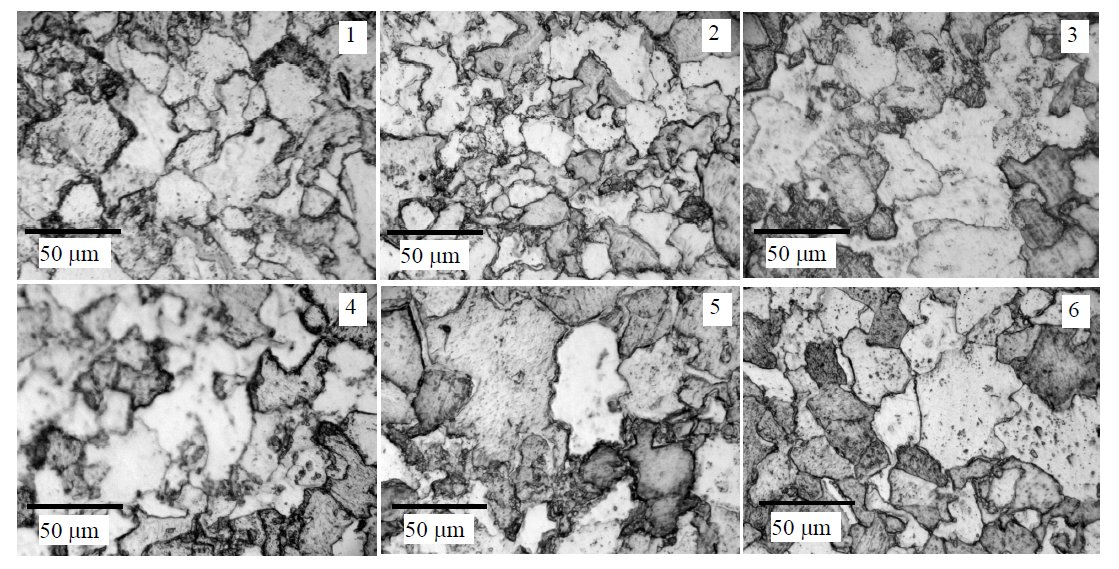

Figure 2: Optical microstructure of 12Kh1MF steel tempered at 700 °C (hours) and etched by 10 % ferrous (III) chloride solution:

1 – virgin steel, 2 – 24, 3 – 48, 4 – 144, 5 – 384 hours, 6 – exploited 227000 hours at 550 °C. Scale bars: 50 µm.

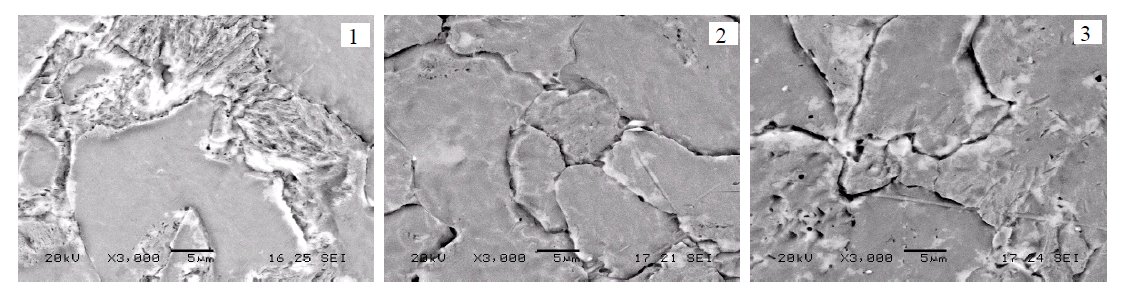

Figure 3: Microstructure (SEM) of 12Kh1MF steel tempered at 700 °C: 1 – virgin state, ferrite-pearlite; 2 – 384 h heated, partial

disintegration of pearlitic structure; 3 – 227000 h exploited at 550 °C, full disintegration of pearlitic structure. Scale bars: 5 µm.

Figure 4: X-ray diffraction patterns of 12Kh1MF steel tempered at 600 °C. Curves: 1 – virgin steel, 2 – 48 h, 3 – 216 h, 4 – 384 h, 5 – 854 h.

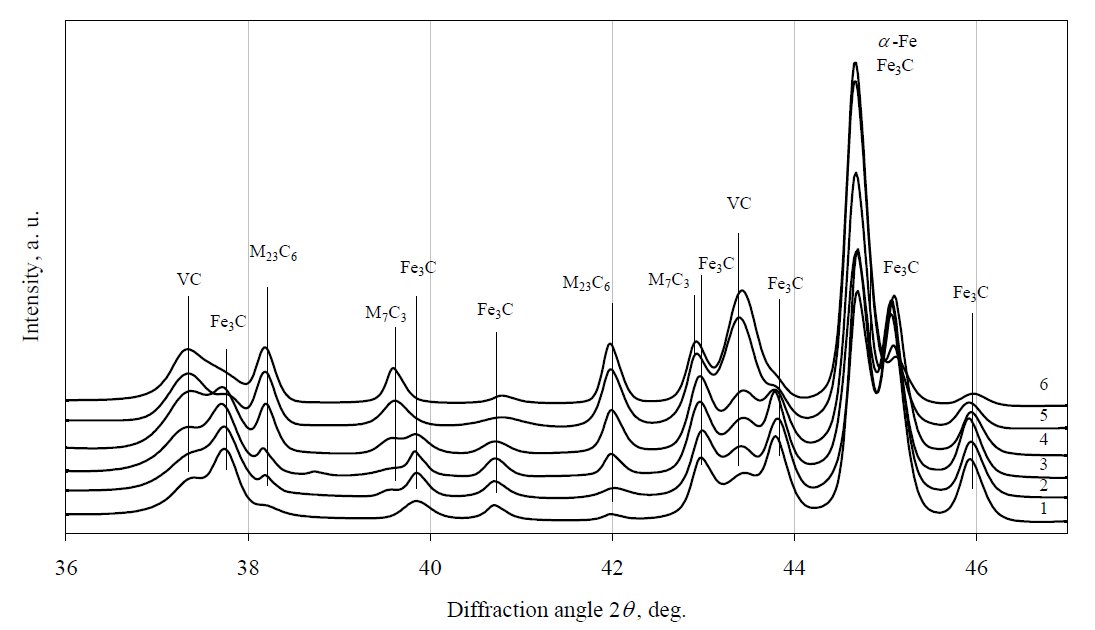

Figure 5: X-ray diffraction patterns of 12Kh1MF steel tempered at 650 °C. Curves: 1 – virgin steel, 2 – 24 h, 3 – 192 h, 4 – 288 h,

5 – 384 h, 6 – 854 h.

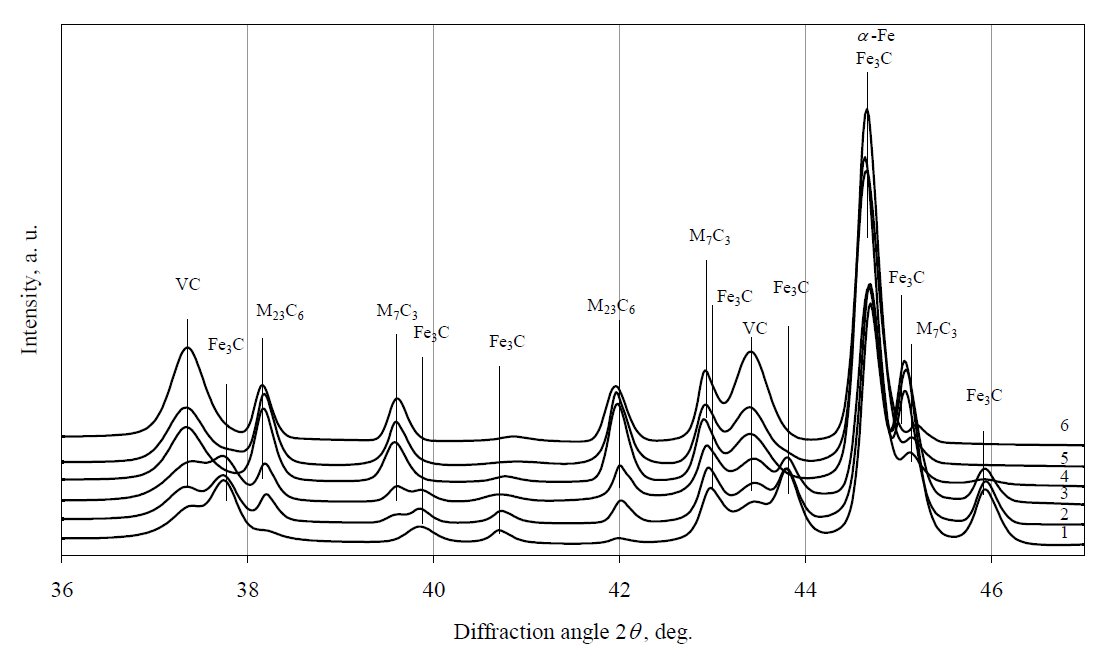

Figure 6: X-ray diffraction patterns of 12Kh1MF steel tempered at 700 °C. Curves: 1 – virgin steel, 2 – 24 h, 3 – 48 h, 4 – 192 h, 5 – 384 h,

6 – 576 h.

Carbide name: Fe3C, VC, M7C3, M23C6

Record No.: 849

Carbide formula: Fe3C, VC, M7C3, M23C6

Carbide type: M3C, MC, M7C3, M23C6

Carbide composition in weight %: No data

Image type: SEM, XRD

Steel name: 12Kh1MF

Mat.No. (Wr.Nr.) designation: No data

DIN designation: No data

AISI/SAE/ASTM designation: ASTM: F12C1.1

Other designation: EN: 13CrMo4-5

Steel group: Heat resistant steels

Steel composition in weight %: 0.12% C, 1.1% Cr, 0.54% Mn, 0.26% Mo, 0.26% Si, 0.17% V, 0.019% S, 0.015% P.

Heat treatment/condition: Investigated 12X1M. steel was taken from a thick

section of superheated steam pipes originally supplied by

SC “Lietuvos elektrine”. The samples were prepared from

virgin and exploited for 227000 h at 14 MPa pressure and

550 °C – 560 °C steel. Using a potentiostat PI-50-1 and a

programmer PER-8 steel anodic polarization curves

(e. g. dependence of operating electrode potential on

current density) were recorded in solutions of different

electrolytes, electrochemical etching solutions and the

parameters (critical current density, critical potential) were

determined.

The samples (60 mm × 20 mm × 20 mm, working area

2.2 cm2 ÷ 2.5 cm2) of 12X1M. steel were soaked into 20 °C electrolyte solution and current measurements were

carried out according argentums chloride reference electrode

(EVL – 1M3.1), when the sample potential from the

stationary value to 1.2 V varied at 1·10–3 V/s or 5·10–3 V/s

rate. Performing anodic polarization of heat resistant steel,

Fe ions, which forms insoluble bivalent and then trivalent

ferrous hydroxides (Fe(OH)2, Fe(OH)3), enter the electrolyte

solution. Anodic polarization curves were recorded in 0.05 %

and 0.5 % hydrochloric acid solution and in hydrochloric

solution with 0.01 % and 0.05 % oxalic or citric acid

concentrations.

Note: Parameters of carbide phase electrochemical separation in electrolytes solutions of pearlitic 12Kh1MF heat resistant

steel, used in thermal power plants facilities are presented in the article. The most relevant electrolyte is chosen and its

concentration is specified. Operated and under laboratory conditions aged steel surface microstructure and morphology

were evaluated by optic and scanning electron microscopy methods. Using electrochemical etching and XRD qualitative

analysis of carbide compounds of 550 °C exploited steel and aged under laboratory conditions at 600, 650, 700 °C from

24 h up to 864 h was carried out. Kinetics of carbides formation is given in mathematical equations. It was determined

that during exploitation and ageing samples at 700 °C for 576 h the steel pearlite completely decomposes, whereas alloy

elements diffuse into intergrain area thus forming special alloy carbides. Experiments revealed that the XRD analysis of

electrochemically separated carbide phase is a rapid and informative method of evaluation the service condition of steel.

The initial microstructure of power plant alloy 12Kh1MF consists of ferrite-pearlite or

ferrite-bainite as the major phases obtained following a

hardening and normalizing heat treatment later on subjected

to very severe tempering (~650 °C…700 °C for

several hours) generating the overall coarsening and the

precipitation of ever more stable alloy carbides and

intermetallic compounds (Fig. 1, curve 1), witch interfere

with the progress of dislocations. These solid state

reactions eventually determine the properties and

mechanical stability of the power plant steels (for example,

the resistance to creep deformation) and their useful design

lifetimes.

In the heat and power generating plants, the pipelines

are used to transport superheated steam in the temperature

range 500 °C – 560 °C and under a pressure,

P = 10 MPa – 15 MPa. During long time service in creep

regime to such conditions the microstructure of steel

changes, pearlite/bainite decomposes as well as carbides

precipitation at the grain boundaries and carbides coarsening

processes proceed (Fig. 1, curve 2). Structure changes

cause formation of cavities and development of internal

damages. It is well known that there is a close coherence

between changes in microstructure and deterioration

of mechanical properties, however, the accurate relation for creep rupture strength deterioration regarding the

microstructural degradation is not yet determined.

Microstructure changes of 12Kh1MF steel surface

during its ageing were observed using optic microscopy

and scanning electron microscopy methods. In optical microscopy photos (Fig. 2, picture 1) of

untreated steel pearlite and ferrite grains are observed,

however it is hard to identify fine carbide compositions.

High temperature ferrite and pearlite grains begin to decompose and in their limits the chains (Fig. 3, pictures

2 – 6) of alloyed carbides are formed, which are difficult to

see in pictures since both the resolution, depth of field and

range of magnifications (to about 550×) of the light

microscope are not sufficient.

The ongoing structure changes of samples and

nucleation of voids may be analysed in an objective way

with the scanning electron microscope. In SEM pictures

(Fig. 3) the steel ferrite-pearlite structure can be clearly

seen. After treating the sample for 384 h at 700 °C, the

pearlitic structure partially decomposes (Fig. 4, picture 2),

whereas in the photo of the sample treated for 227000 h at

550 °C, a full disintegration of pearlitic structure (Fig. 3,

picture 3) is recorded.

XRD analysis was used to confirm carbides formation

in steels during their ageing as well as to perform kinetics

research. According to the steel critical current density,

determined by anodic polarization method, steel etching

operating current density was chosen. Its value corresponds

to approximately half critical current density. Since

for real samples due to approximately 10 times bigger

surface area the analysed 0.05 % electrolyte concentration

was too small (steel solution process ended very quickly,

when a sufficient amount of carbide phase had not yet been

released), it was increased up to 5 %.

Fig. 4 shows X-ray diffraction patterns of electrolytically

extracted residues of specimens during the early stages of

tempering at 600 °C. After 48 h tempering exposure, intensity

of diffraction peaks of Fe3C, VC and traces of M23C6 (M

stands for metals: iron, chromium, molybdenum and vanadium)

remains almost unchanged but small amount of M7C3

has been detected (Fig. 4, curve 2). After 216 h accelerated

ageing the diffraction peak of carbide M23C6 considerably

increases (Fig. 4, curve 3) while Fe3C diffraction peak

marginally diminishes. The most significant changes have

been identified after 654 h isothermal ageing (Fig. 4, curve 5).

The intensity of M23C6, VC and M7C3 diffraction peaks

considerably increase, while Fe3C significantly decreases. All

the data showed that tempering causes the Fe-rich M3C

carbide (the kinetically favoured phase in the pearlite) to

transform to more thermodynamically favoured carbides,

rich in Cr and Mo. The most thermodynamically stable

carbide M6C was not yet identified.

After further performing XRD analysis of the samples,

it was determined that during ageing of 12Kh1MF steel at

650 °C and 700 °C (Fig. 5 and Fig. 6), the concentration of

Fe3C reduces more rapidly and, at the same time, the rate of transformation to M23C6 alloy carbide is accelerated. No

precipitation of stable carbide M6C was detected too. So,

the same carbide precipitation sequence was observed at

650 °C and 700 °C as it was detected at 600 °C, although

the precipitation kinetics appears to be faster for all phases

at that temperatures. Because the carbide M6C have been

detected in 12Kh1MF steel exploited for 227000 h, thus it

would be meaningful to continue experiments at elevated

temperatures to obtain conditions of full carbide

precipitation sequence. These results would be useful for

evaluation of steel service time and for prediction remnant

life.

Links: No data

Reference: Not shown in this demo version.