Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Alloy Carbides

The addition to iron-carbon alloys of elements such as Ni, Si, Mn, which do

not form carbides in competition with cementite, does not basically alter the

microstructures formed after transformation. However, in the case of strong

carbide-forming elements such as Mo, Cr and W, cementite will be replaced by

the appropriate alloy carbides, often at relatively low alloying element

concentrations. Still stronger carbide- forming elements such as Nb, Ti and V are

capable of forming alloy carbides preferentially at alloying concentrations less

than 0.1 wt%. It would, therefore, be expected that the microstructures of steels

containing these elements would be radically altered.

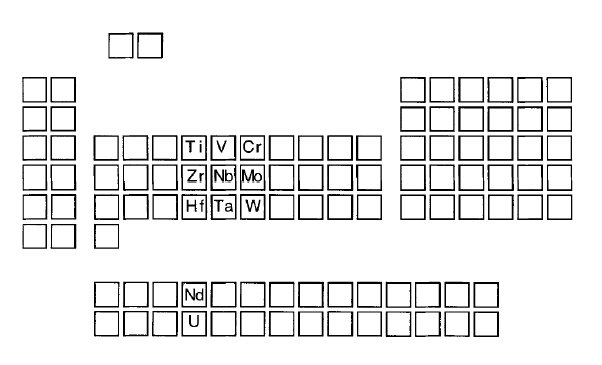

Carbides are formed in steels only by iron and metals that stand to the left of

iron in the periodic table. The strong carbide-forming elements are shown in Fig. 1.

Figure 1: The periodic table showing the positions of strong carbide-forming elements.

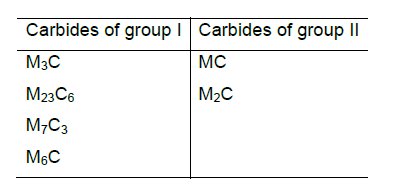

In steel six kinds of carbides can be formed as shown in Table 1, where M denotes a sum of carbide-forming (metal) elements. The carbides placed in group I posses a complicated crystal structure; an examples is cementite (Fe3C), or Cr23C6. A specific structural feature of the carbides of group II as interstitial phases is a simple crystal lattice (e.g., TiC, WC, NbC and Mo2C).

Table 1: Possible variants of carbide formation in steels.

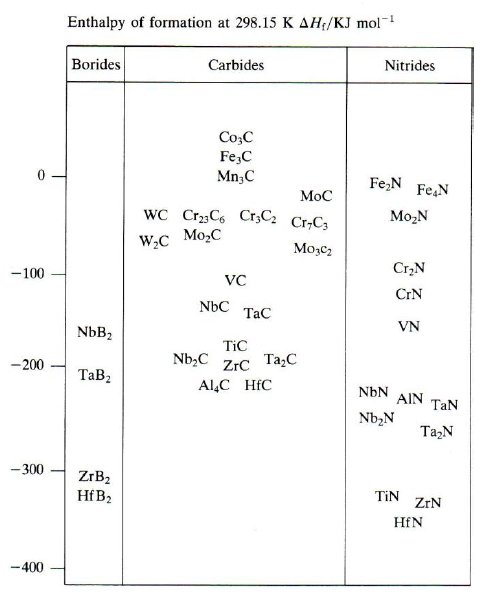

The stability of the alloy carbides and nitrides in steels relative to that of cementite is shown in Fig. 2, where the enthalpies of formation (Hf) are plotted (cementite is the reference, i.e. Hf-cementite=0). It should be noted that the effectiveness of the carbides as strengtheners depends on the fineness of the dispersion and the volume fraction precipitated. The fineness of the dispersion depends on the activation energy barrier (G*) for nucleation which in turn is influenced by the free energy of formation of the carbide, the interfacial energy and the misfit. Fig. 2 can be used as a guide in this regard. The finest precipitate dispersions are generally obtained from VC, NbC, TiC, TaC and HfC. Theseare all close-packed intermetallic compounds. On the other hand the carbides with complex crystal structures and low heats of formation, e.g. M7C3, M6C and M23C6, generally form relatively coarse dispersions.

Figure 2: Enthalpies of formation of carbides, nitrides and borides.

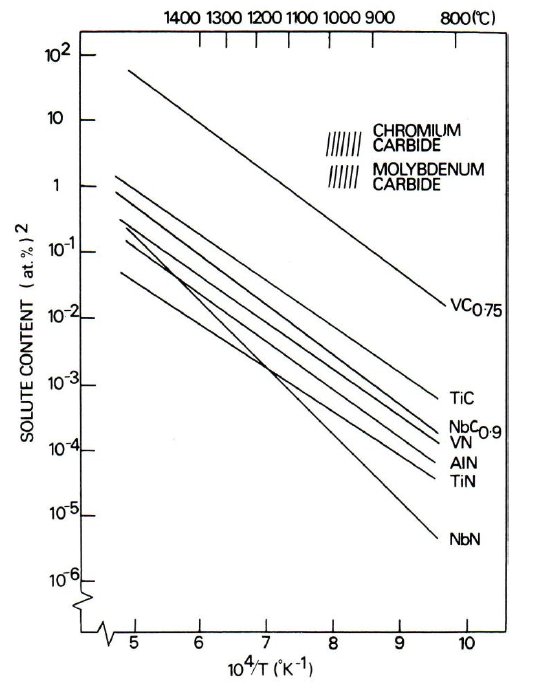

The volume fraction of carbide precipitated depends on the solubility of the alloy carbide in the austenite prior to quenching, relative to the solubility in ferrite. Fig. 3 shows the solubility products of various carbides and nitrides in austenite as a function of temperature. The solubilities of these compounds in ferrite are very much lower and to a first approximation can be considered to be approximately equal. It is clear therefore that chromium, molybdenum and vanadium with highest solubilities in austenite, should precipitate in the highest volume fractions in the ferrite.

Figure 3: Solubility product of carbides and nitrides in austenite as a function of temperature.

Reference: Mehran Maalekian, The Effects of Alloying Elements on Steels (I), Technische Universität Graz, Institut für Werkstoffkunde, Schweißtechnik und Spanlose Formgebungsverfahren, Christian Doppler Laboratory for Early Stages of Precipitation, October 2007, pp. 10-13.