Alphabetical Index

Chemical Composition of Steels

Keyword Search

Steel Names

Alloyed Steels

Carbon Steels

Cast Irons

Chromium Steels

Cold Work Tool Steels

Creep Resistant Steels

Hot Work Tool Steels

Molybdenum Steels

PM steels

Stainless Steels

Structural Steels

Tool Steels

Vanadium Steels

White Cast Irons

M2C Carbides

M3C Carbides

M7C3 Carbides

M23C6 Carbides

MC Carbides

Light Microscopy

EDS/WDS Microanalysis

Scanning Electron Microscopy

Transmission Electron Microscopy

X-Ray Diffraction

Help

Contact Us

Home

Carbide Extraction From the Weldox Steel

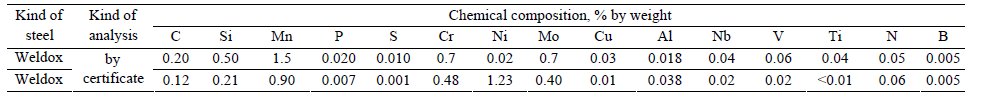

Table 1: Chemical composition of the investigated steels.

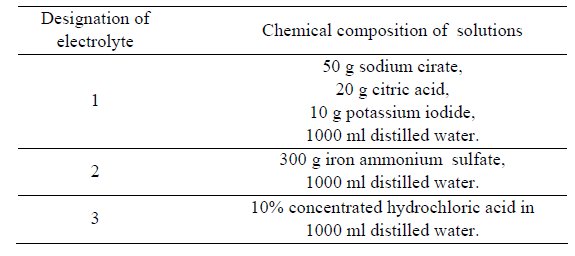

Table 2: The composition of electrolyte–solutions applied for the anodic

dissolution of the investigated steels by PN 64/H-04510.

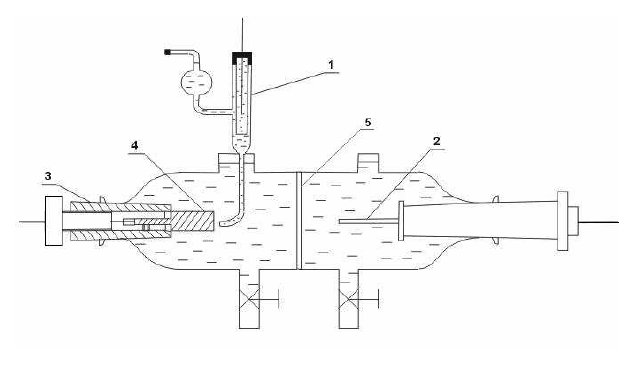

Figure 1: Diagram of an electrolyzer for the anodic solution of

Weldox steels: 1-Haber-Lugin capillary with a reference

electrode, 2-auxiliary electrode (cathode), 3-holder of the tested

electrode, 4-sample (anode), 5- diaphragm made of sinter glass.

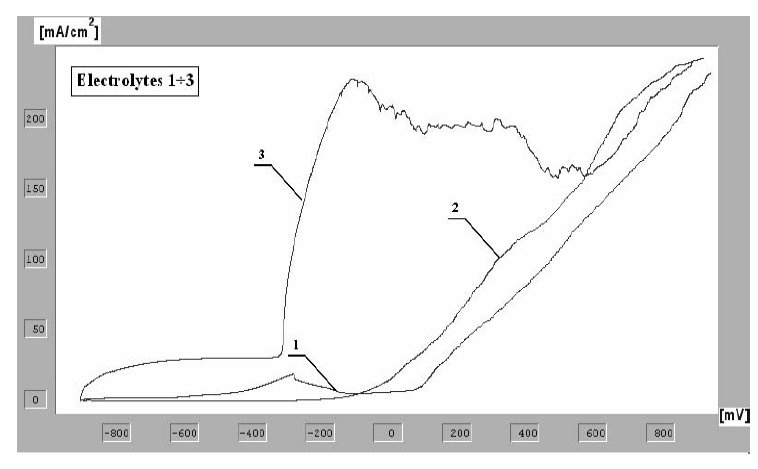

Figure 2: Potentiodynamic curves of the anodic polarization for Weldox

1300 steel obtained by the method of linear voltamperometry for

various electrolytic solutions.

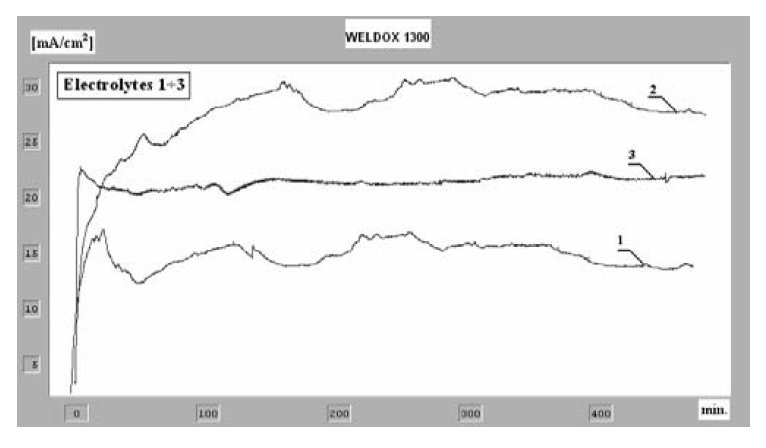

Figure 3: Chronoamperometric curves of the anodic polarization for

Weldox 1300 steel in various electrolytic solutions.

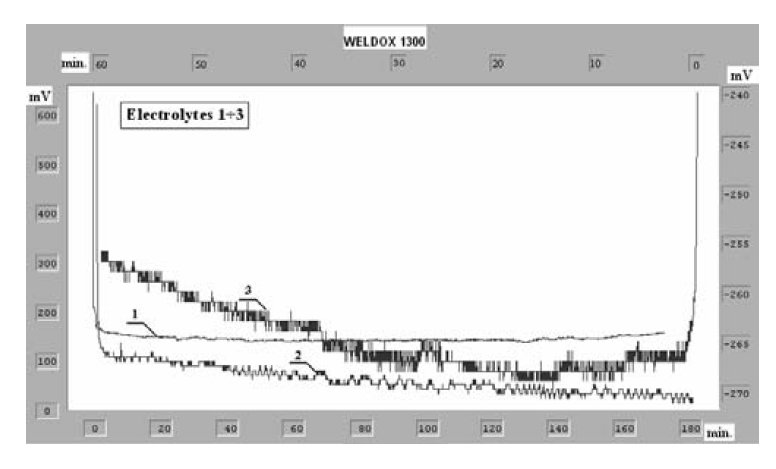

Figure 4: Chronopotentiometric curves of the anodic polarization for

Weldox 1300 steel in various electrolytic solutions.

Investigations were carried out on high-resistant microalloyed

constructional Weldox steels, resulting from industrial smelting in

the Swedish firm SSAB (Oxelösund). The chemical composition

of the investigated steels is to be seen in Table 1. The material

was supplied in the form of steel sheets, with a thickness of 20 mm (Weldox 900) and 10 mm (Weldox 1300). These sheets were

sampled for anodic dissolution (Ø7 mm and Ø15 mm and the

length 40 mm) and measurements of their hardness and for

metallographic investigations. The hardness of steel Weldox 900

in the delivered state amounts to about 34 HRC, and that of

Weldox 1300 to about 48 HRC. Metallographic observations have

revealed in these steels a fine dispersive structure of tempered

martensite with various morphologies.

Electrochemical investigations comprised the determination of

the active potential of dissolution of the investigated steels in various

chemical reagents (Table 2) and anodic dissolution both by means of

the chronopotentiometric method (at a constant current) and the

chronoamperometric method (at a constant potential.

The dissolution of electrochemically active phases in a given

electrolyte solution was controlled potentiostatically by keeping

the given potential versus the reference electrode (saturated

calomel electrode, SCE). For this purpose curves of anodic

polarization I=f(E) were plotted determining the dependence of

the rate of dissolution on the assumed potential, and the ranges of

active dissolution and anodic passivation of the metal were found.

The dependence permitted to determine the potentional, at which

the ratio of the dissolution rate of the matrix versus the

precipitation reaches the highest values.

The anodic polarization curves of the investigated steels were

determined potentialdynamically making use of a glass

electrolyzer (Fig. 1) and a PGP 201 potentiostat from the firm

Radiometric Copenhagen which is a part of the system

VoltaLab21 cooperating with the personal computer.

The curves of anodic polarization determined for various

solutions are to be seen in Fig. 2.

Chronoamperometric and chronopotentiometric curves of the

anodic dissolution of Weldox 1300 steel in the investigated

solutions have been presented in Figs. 3. and 4.

X-ray investigations of electrolytic extractions were run by

means of an X-ray diffractometer type XRD 7, produced by

Seifert-FPM, applying the radiation of an anode CoKalpha and a Fe -

filter. Electrolytic extractions, deposited on a filter paper were

analyzed within the range of angles 2theta from 1 deg 2theta. The

step-scanning method was used at a step value of 0.1 deg 2heta and a

time of measurements amounting to 7 seconds in one

measurement position. The obtained diffraction patterns were

analyzed applying the program Diffract AT Search/Match.

Reference: W. Ozgowicz, A. Kurc, G. Nawrat, Identification of precipitations in

anodically dissolved high-strength microalloyed Weldox steels, Archives of Materials Science and Engineering, Volume 31, Issue 2, June 2008, pp. 96-97.